Failure Mode & Effects Analysis (FMEA)

Failure Mode and Effects Analysis (FMEA) is a model used to prioritize potential defects based on their severity, expected frequency, and likelihood of detection.

An FMEA can be performed on a design or a process, and is used to prompt actions to improve design or process robustness. The FMEA highlights weaknesses in the current design or process in terms of the customer, and is an excellent vehicle to prioritize and organize continuous improvement efforts on areas which offer the greatest return.

How to Start

The process is very straightforward, and begins by identifying all of the probable failure modes. This analysis is based on experience, review, and brainstorming, and should use actual data if possible.

New designs or processes may not have actual historical data to draw from, but "proxy" data may be available from similar designs or processes. The next step is to assign a value on a 1-10 scale for the:

- severity ,

- probability of occurrence ,

- and probability of detection

for each of the potential failure modes. After assigning a value, the three numbers for each failure mode are multiplied together to yield a Risk Priority Number (RPN).

The RPN becomes a priority value to rank the failure modes, with the highest number demanding the most urgent improvement activity. Error-proofing, or poka-yoke actions are often an effective response to high RPN's.

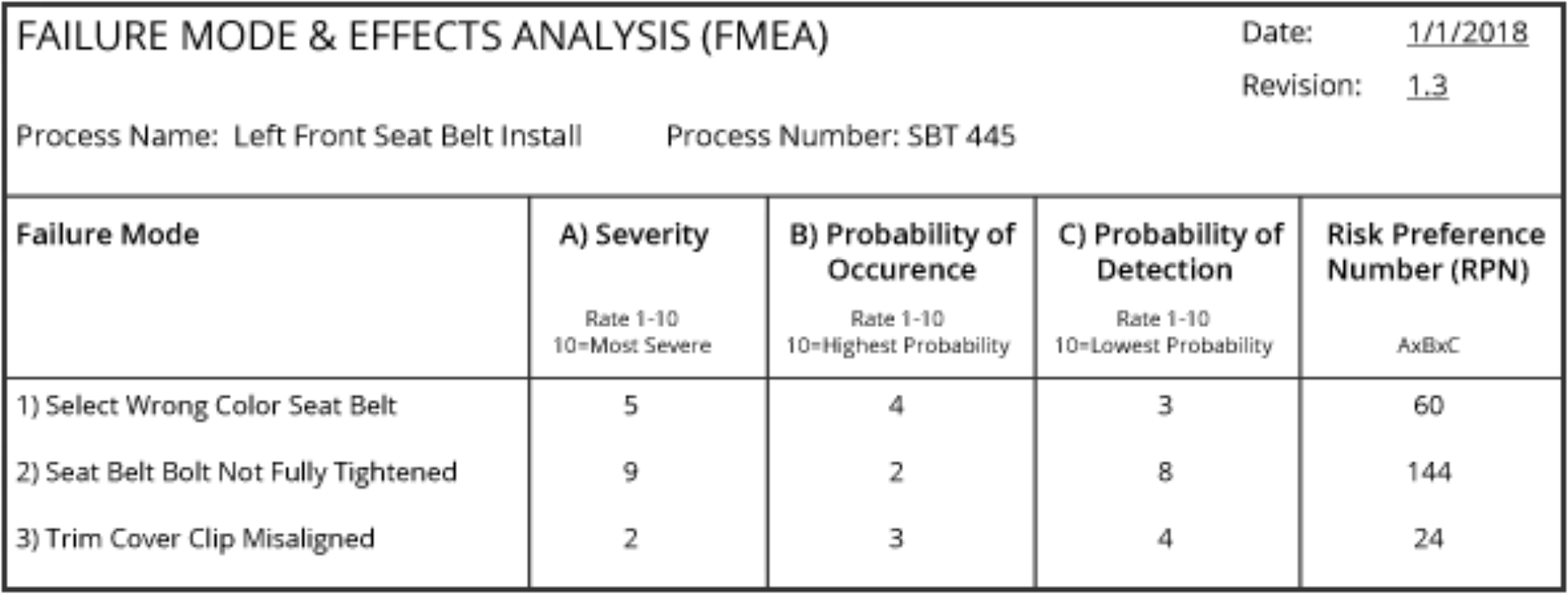

FMEA Example

Here is an example of a simplified FMEA for a seat belt installation process at an automobile assembly plant.

As you can see, three potential failure modes have been identified. Failure mode number two has an RPN of 144, and is therefore the highest priority for process improvement.

FMEA's are often completed as part of a new product launch process. RPN minimum targets may be established to ensure a given level of process capability before shipping product to customers. In that event, it is wise to establish guidelines for assessing the values for Severity, Occurrence, and Detection to make the RPN as objective as possible.

Choosing the Right FMEA Software

Having the foresight to anticipate potential process or design issues can lead to proactive problem-solving efforts instead of “firefighting” – but not all problems are created equal. EngineRoom’s FMEA documentation tool offers a quick and easy route for identifying high-ROI issues and analyzing how improvements change the outlook.

With EngineRoom’s FMEA documentation tool, users can quickly input project steps and their associated failure modes and then assign scores for their severity, occurrence, and likelihood of detection. For each of these three defects, it’s possible to customize criteria for each score in the reference table below.

After EngineRoom automatically calculates the Risk Priority Number, it’s also possible to re-score this critical piece of data by factoring in revised post-improvement scores. This feature can be toggled on or off. With EngineRoom’s FMEA tool, teams can quickly and efficiently determine where to direct problem-solving resources and assess how those efforts are making an impact.

Summary

The failure mode and effects analysis model can help teams decrease project scope and complexity by focusing in on the primary failure modes of a process. Creating an FMEA is best done by coordinating a cross-functional team and using objective and subjective knowledge to identify accurate properties about the identified failure modes.