The Beginner's Guide to Discrete Event Simulation

January 11, 2025What is Discrete Event Simulation (DES)?

Discrete Event Simulation (DES) is a technique for modeling and analyzing the behavior of systems over time. It works by breaking a system into a series of discrete events that occur in sequence. Each event represents a change in the system’s state, such as a customer arriving at a queue or a machine completing a task. By simulating these events in sequence, DES enables users to study and predict system behavior under various conditions.

DES is widely used in fields ranging from healthcare and manufacturing to logistics and service design. If you're looking for a broader technical overview, this article on discrete event simulation provides a helpful summary of its foundational concepts and applications.

The Importance of DES

Traditional Lean tools like line balancing, operator run charts, and Takt time analyses have long been valuable for operational improvements. However, the increasing pace and variability in modern processes require tools that go beyond "average" conditions. Discrete Event Simulation (DES) meets this need by creating a digital twin of the process, replicating real-world variability and providing deeper insights into process dynamics.

What makes DES especially powerful is its ability to show how disturbances—such as unexpected delays or surges in demand—can disrupt steady operations and build up variability. More importantly, DES reveals how the system responds and recovers from these disruptions. This dynamic approach helps teams identify hidden weaknesses, such as bottlenecks or cascading delays, and design processes that are not only efficient but also resilient to real-world challenges.

How Do DES Models Work?

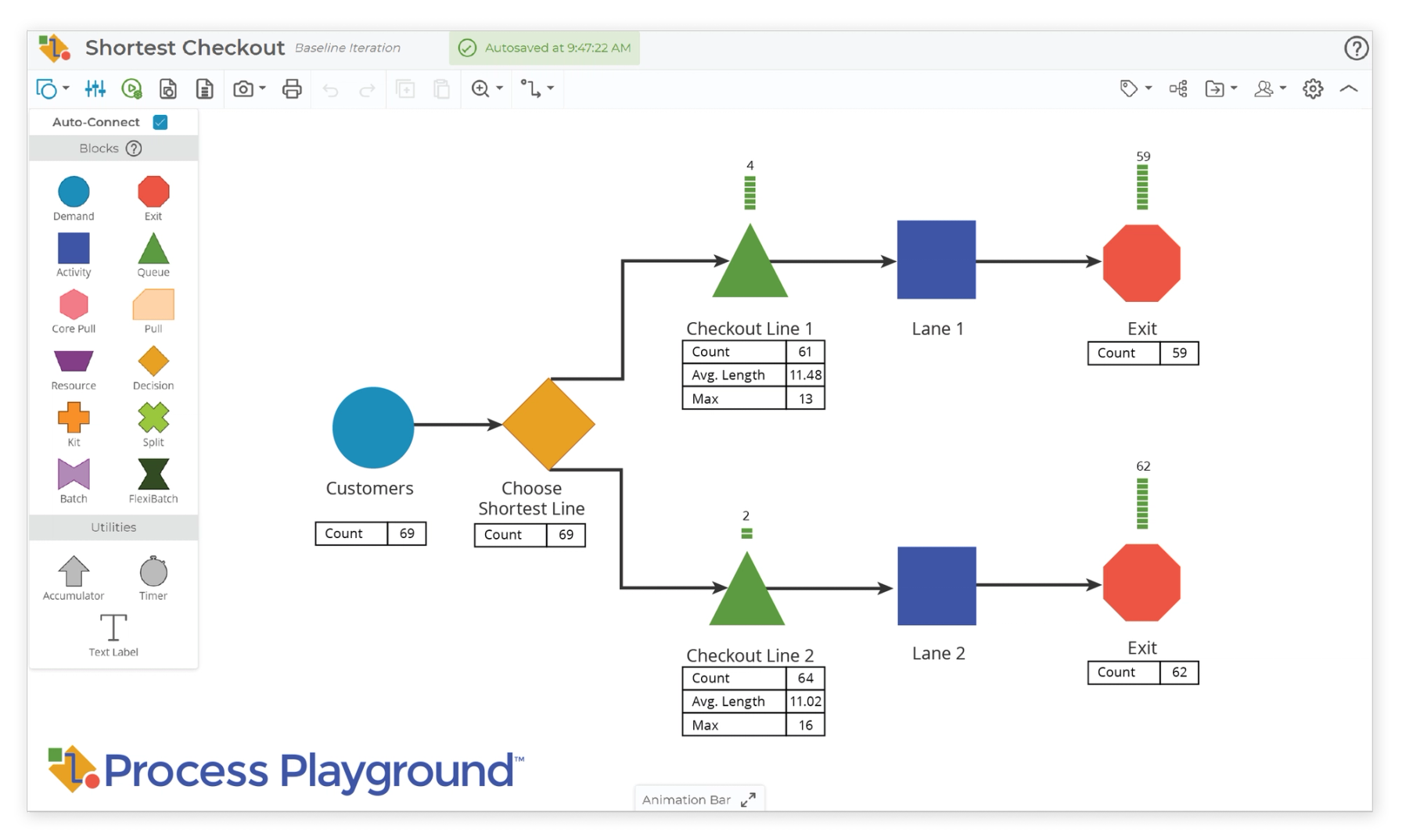

DES models represent systems by defining key components:

- Items: The objects being simulated, such as customers, products, or machines.

- Events: Points in time where a system state changes (e.g., arrival of a new customer, completion of a task).

- Queues: Holding areas for entities waiting for resources (e.g., customers in line).

- Resources: Limited assets required to complete tasks (e.g., staff, machines).

- State Variables: Attributes defining the current state of the system (e.g., number of entities in a queue).

At each simulated time step, DES evaluates whether conditions trigger a change in the system’s state. For example, in a retail store simulation, the system might check whether a new customer arrives or a checkout task is completed. State variables, such as queue length, are updated to reflect these changes. By incorporating randomness and variability—like arrival times or task durations—DES captures the complex, dynamic behavior of real-world systems.

Steps to Build a Discrete Event Simulation Model

Building a Discrete Event Simulation (DES) model involves several steps to accurately represent and analyze your process. Here's a straightforward guide:

- Map Your Process: Begin by identifying all key steps in the process and the different paths items take. It's crucial to define the scope carefully—modeling too much can waste time on areas that aren't problematic or can't be changed. Focus on the portions of the process that matter most for achieving your objectives.

- Identify Flow Items: Determine what is flowing through your process—whether it's customers, products, or tasks. For simpler processes, you might treat all demand as a single group. For more complex systems, segment demand into categories that follow unique paths or interact differently with parts of the process.

- Analyze Arrival and Processing Times: Collect and analyze data to determine the mathematical distributions that best represent how items arrive and how long they take at each step. Use statistical tools to identify the appropriate distributions, such as exponential, triangular, or normal, ensuring your model accurately reflects real-world variability.

- Gather Descriptive Statistics: Collect key performance metrics from your live process, such as inventory levels, utilization rates, and throughput. These statistics serve as a benchmark to evaluate the accuracy of your model.

- Validate the Model: Run your simulation and compare its output to the live process data. If the results don’t align, refine your inputs or assumptions until the model accurately reflects the real system. Validation ensures that your model can reliably predict system performance under different scenarios.

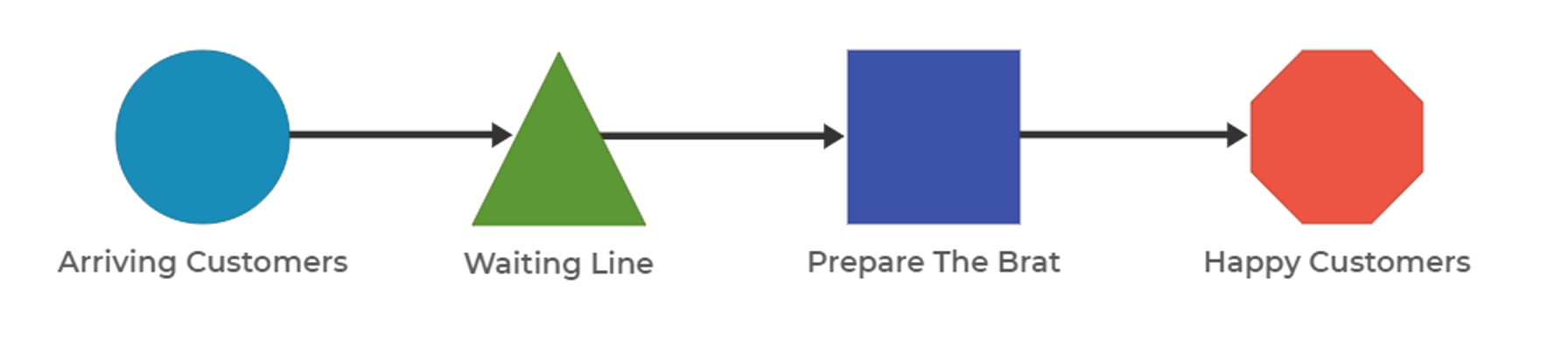

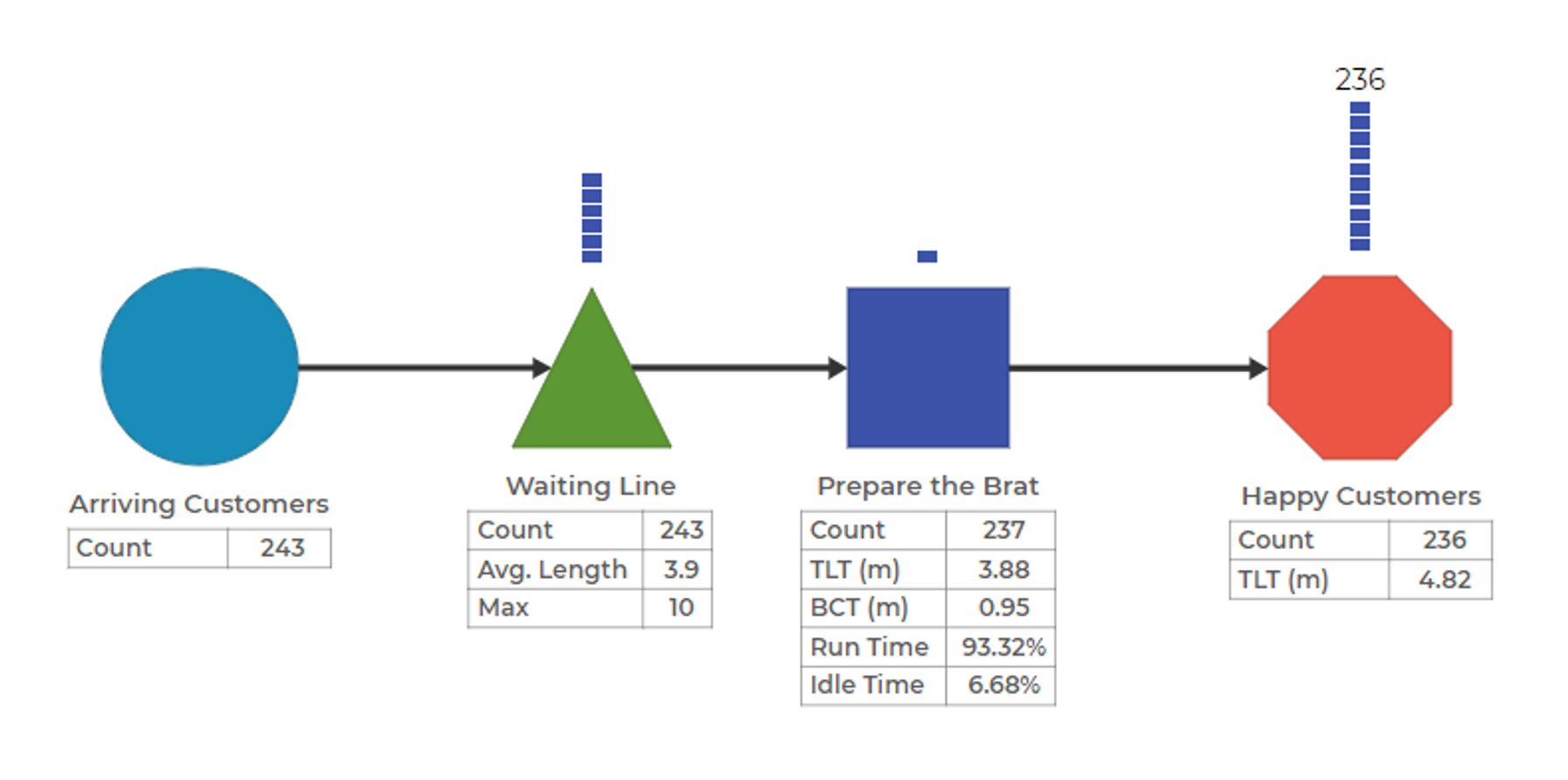

Example of a DES Model

Let’s consider Kathy’s Best Wursts, a food stand at a local sporting event. Customers arrive at the stand at an average rate of one customer per minute, with arrival times being highly variable and following an exponential distribution. Upon arrival, customers wait in line until Kathy is ready to serve them. Kathy’s process involves preparing each brat, including adding the requested toppings. This task takes an average of 55 seconds, with a minimum of 40 seconds and a maximum of 70 seconds, modeled using a triangular distribution. Once served, customers leave the system.

Here are the basic process parameters that define Kathy's Best Wursts at this point:

- Customer demand averages one customer per minute. It is highly variable and appears to be exponentially distributed.

- Kathy prepares the brat, placing it in the bun and adding the requested fixings. This task takes her 55 seconds on average but can range between 40 and 70 seconds, depending on the number of fixings. The task time is well modeled by the triangular distribution, with mode = 55, min = 40, and max = 70.

- Kathy's Best Wursts is usually open for business for four hours during most events.

Assuming the stand operates for four hours, this model could be used to predict average wait times, assess Kathy’s ability to meet demand during peak hours, and identify the impact of reducing preparation time on customer satisfaction.

Reasons to use DES models

DES models are versatile tools used for designing new operational processes or improving the behavior and performance of existing ones through redesign. Discrete Event Simulation software provides deep insights into the impact of variability and variation, parallel and series task sequences, resource and material constraints, fluctuating product and service demands, and many other factors that affect system performance. You can leverage DES models to:

- Visualize & Understand a Process or System: Create a digital twin of your process to see how it operates under different conditions.

- Reduce Implementation Risk: Test proposed changes virtually to ensure they’re viable before applying them.

- Build Confidence in Change Proposals: Use simulations to demonstrate potential improvements to stakeholders.

- Analyze & Optimize Performance: Identify bottlenecks, minimize waste, and enhance throughput.

- Evaluate Process Alternatives: Compare different strategies to find the best solution for your system.

- Improve System Design: Refine your process to handle variability and resource constraints.

- Understand the Impact of Variation: Simulate scenarios to uncover how fluctuations affect outcomes.

- Diagnose Process Issues: Identify root causes of inefficiencies or delays in your system.

- Explore Process Improvements: Experiment with changes and visualize their effects in real-time.

Why You Should Add Process Modeling Using DES to Your Process Improvement Toolbox

DES excels by modeling variability, randomness, and interdependencies—areas where traditional tools like value stream mapping fall short. For Lean Six Sigma practitioners, DES bridges the gap between conceptual tools and real-world complexities, enabling more effective problem-solving and process optimization.

Key Benefits for Continuous Improvement Practitioners:

- Model the effects of variability on system performance.

- Test changes without disrupting live operations.

- Showcase the impact of improvements to stakeholders.

DES as a Teaching Tool for Lean Six Sigma DES is a powerful educational resource for teaching Lean Six Sigma (LSS) concepts, especially in virtual environments. By simulating real-world scenarios, it helps learners visualize abstract concepts like bottlenecks, variability, and overproduction. For example, a DES model of overproduction can illustrate the costs of excess inventory and waiting times, making the lessons more tangible and memorable.

DES Software: Modeling Should Be For Everyone

While traditional DES tools often require advanced expertise in modeling, Process Playground within EngineRoom removes these barriers with its drag-and-drop interface and predefined blocks, users can quickly create and experiment with process modeling.

Why Choose Process Playground?

- Ease of Use: Create models without needing advanced technical skills.

- Example Library: Start with ready-made templates for common industry scenarios.

- Flexibility: Analyze processes, test ideas, and teach concepts with minimal effort.

Whether diagnosing process issues, evaluating improvements, or teaching Lean Six Sigma, Process Playground makes simulation accessible to all.

The Impact of Process Playground

At Medtronic, where every process improvement directly impacts human lives, Process Playground has become an essential tool in their operational excellence journey. This innovative software enables the creation of virtual process models, allowing teams to identify sources of variation and test process changes in a risk-free environment.

Medtronic's use of Process Playground has yielded remarkable results. In one Green Belt project, it facilitated a virtual examination of production inefficiencies, leading to an 11.6% output improvement without capital expenditure. In another, output nearly doubled while operator and machine utilization soared from 70% to 98%.

Ryan Magnuson, Medtronic's Senior Operational Excellence Program Manager, highlights the tool's impact: “It’s transformed our Lean thinking, enabling us to address variation and creatively solve problems without wasted resources.”

Conclusion

Discrete Event Simulation is an essential tool for anyone looking to improve operational processes. Whether you’re designing new systems, diagnosing issues, or teaching process improvement, DES offers unparalleled insights into complex systems.

Vice President of Marketing • MoreSteam

Lindsay Van Dyne is responsible for developing and executing MoreSteam’s marketing strategy. She brings a deep understanding of Lean Six Sigma, having served as MoreSteam’s eLearning Product Manager for the company’s comprehensive suite of Yellow, Green, and Black Belt courses. Over the years, she has attended dozens of industry conferences, webinars, and workshops, gaining firsthand insight into the evolving needs of continuous improvement professionals.

Her marketing experience includes technical aspects of search engine optimization (SEO), digital content strategy, lead generation, website development, event management, and partner relationships. Lindsay holds a B.S. in Chemical Engineering from the University of Notre Dame and a B.S. in Computational Physics and Mathematics from Bethel College.