Blended Learning Manifesto

Introduction

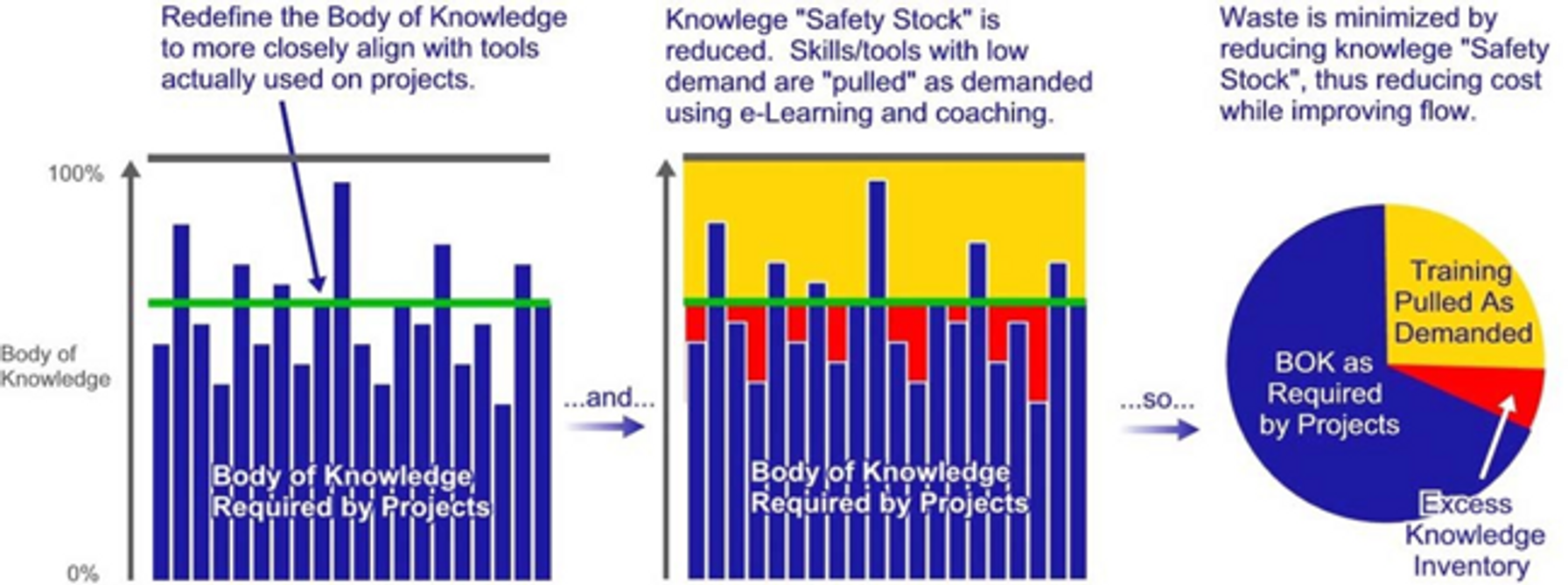

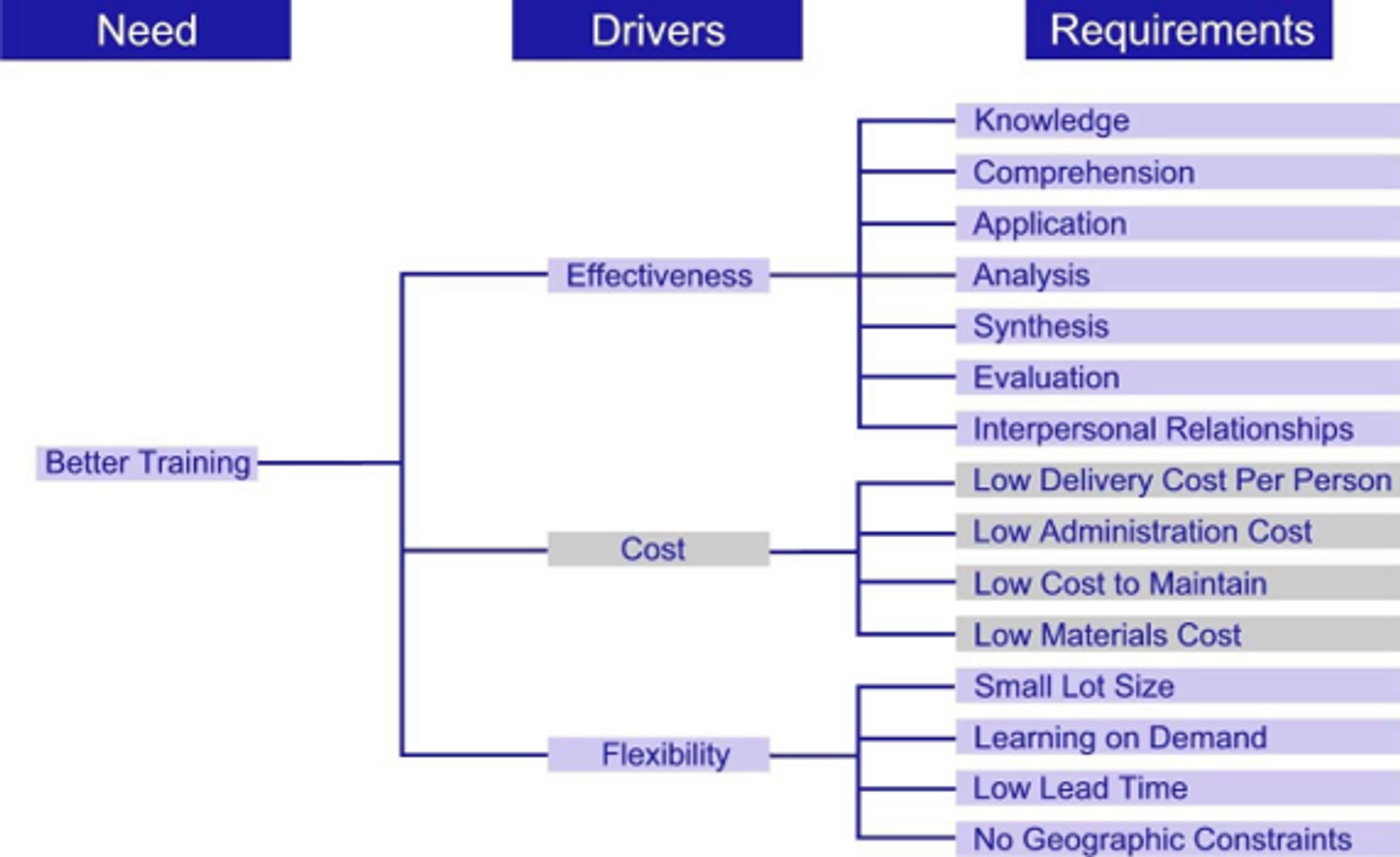

As providers of Lean Six Sigma training, we must apply the tools we teach to the methods we use to teach the tools — to practice what we preach. Consistent with the Lean Six Sigma methodology, we approach this objective from the customer's perspective. Customers of training have three primary drivers to make training better: 1) make the training more effective, 2) make the training less expensive, and 3) make the delivery of training more flexible and responsive. The design of an improved training model must address the critical requirements embodied by these three categories of need. In our experience, blended training models most thoroughly satisfy the range of customer requirements. We define blended training as a training model designed to comprehensively integrate multiple delivery modes and learning activities for a given curriculum — generally including a mix of eLearning, classroom exercises, and coaching.

The design of a specific training model must answer three critical questions:

- What should we teach

- How do we teach it

- How do we draw tight linkage to project work — since that's the whole reason for undertaking the training effort

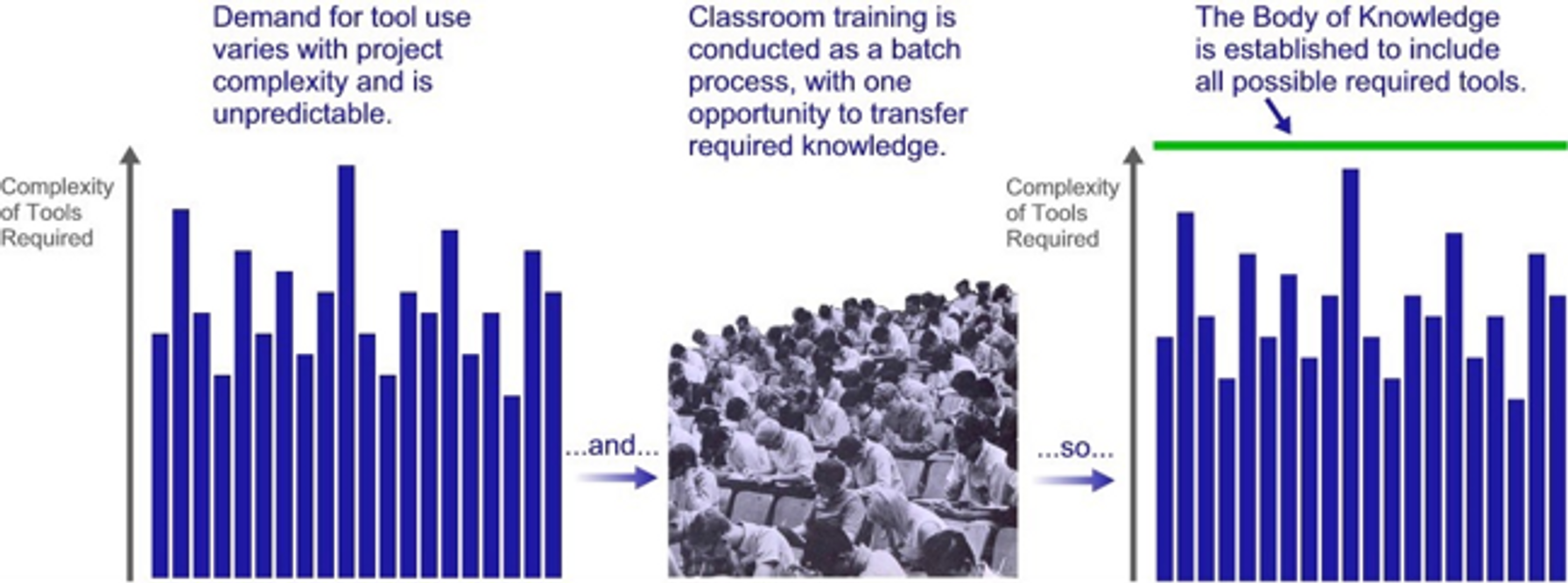

First, let's examine the "what should we teach?" question from a Lean perspective to identify waste. The graphic below represents the baseline condition, which depicts the current state of Lean Six Sigma DMAIC training (Green Belt and Black Belt).

Due to the single batch nature of the classroom training model, the curriculum is designed to cover a body of knowledge that anticipates possible future use — but like all demand forecasts, is ultimately inaccurate. Most projects are executed by drawing upon a much narrower body of knowledge than that taught in the typical training class. This is particularly true of the Green Belts, most acutely in a transactional setting, where the bulk of projects are completed with the more basic tools. Returning to the Lean model, excess knowledge transfer can be considered excess inventory, similar in many respects to tangible inventory, and subject to shrinkage and obsolescence, as shown by the illustration below. Excess knowledge is like "safety stock" — inventory held "just‐in‐case" because demand is unpredictable. Such inventory is one of the seven forms of waste identified by Taiichi Ohno at Toyota.

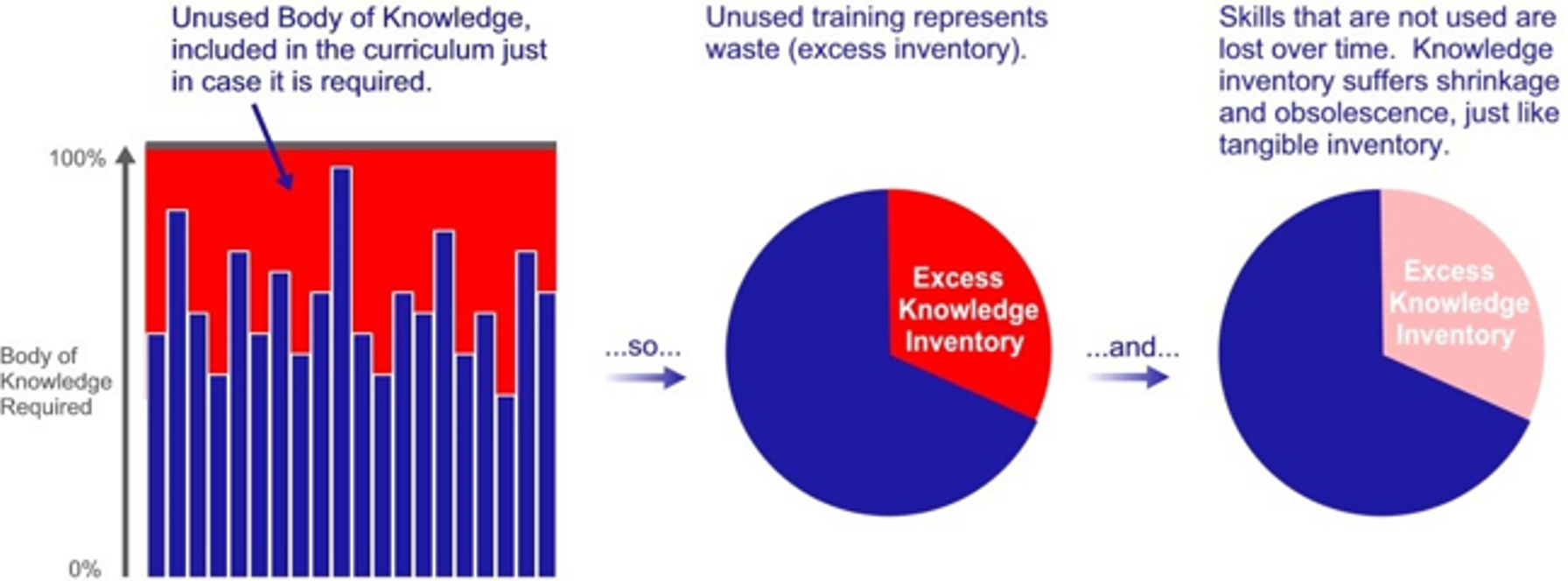

If Lean Six Sigma capability around the more advanced tools could be developed as demanded, and only when demanded, then waste could be eliminated by revising the base curriculum accordingly. By using eLearning paired with coaching, the training model can be migrated away from a pure "push" model, which forces guesswork about which tools will be required by a given "Belt" on a given project, toward a more efficient "pull" system, as shown below:

The first steps to reduce waste and therefore cost in the system are to redefine the curriculum to eliminate the safety stock of knowledge while redesigning the delivery method to move from a "push" to a "pull" system. A critical prerequisite to establishing a pull system is the ability to respond to the pull signal, which requires short lead times and small lot sizes.

Waste Analysis

Using Taiichi Ohno's seven forms of waste, we can further examine the current state of Lean Six Sigma training based on the instructor‐led classroom model:

Defects: Green Belt or Black Belts who can't use the Lean Six Sigma tools appropriately to complete projects; training rework to re‐train skills that did not imbed themselves.

Overproduction: Training Green/Black Belts who don't yet have meaningful projects to work on.

Transportation: Unnecessary travel to physical training events.

Waiting: Delays in training initiation and project work while waiting for a class (batch) to start.

Unnecessary Inventory: Overtraining a wider body of knowledge than that which is required by actual project work.

Unnecessary Motion: Time spent in inefficient training activities which do not effectively build the required skills (over-reliance on lecture vs. active learning); class time spent covering skills that an individual has previously mastered.

Excessive Processing: Using expensive instructor‐led activities when technology could automate the process.

From a Lean Six Sigma perspective, the design of a revised training model should address and resolve all of these forms of waste.

Voice of the Customer

As a first step toward re‐designing the training model, let's examine the customer requirements in greater detail using the tree diagram below. Note that each driver category has been expanded into a group of more specific requirements. The first six requirements under "effectiveness" represent increasing levels of mastery as embodied by Bloom's taxonomy.

Other requirements represent various dimensions of cost, as well as key determinants of flexibility or responsiveness.

Translating Requirements to Design

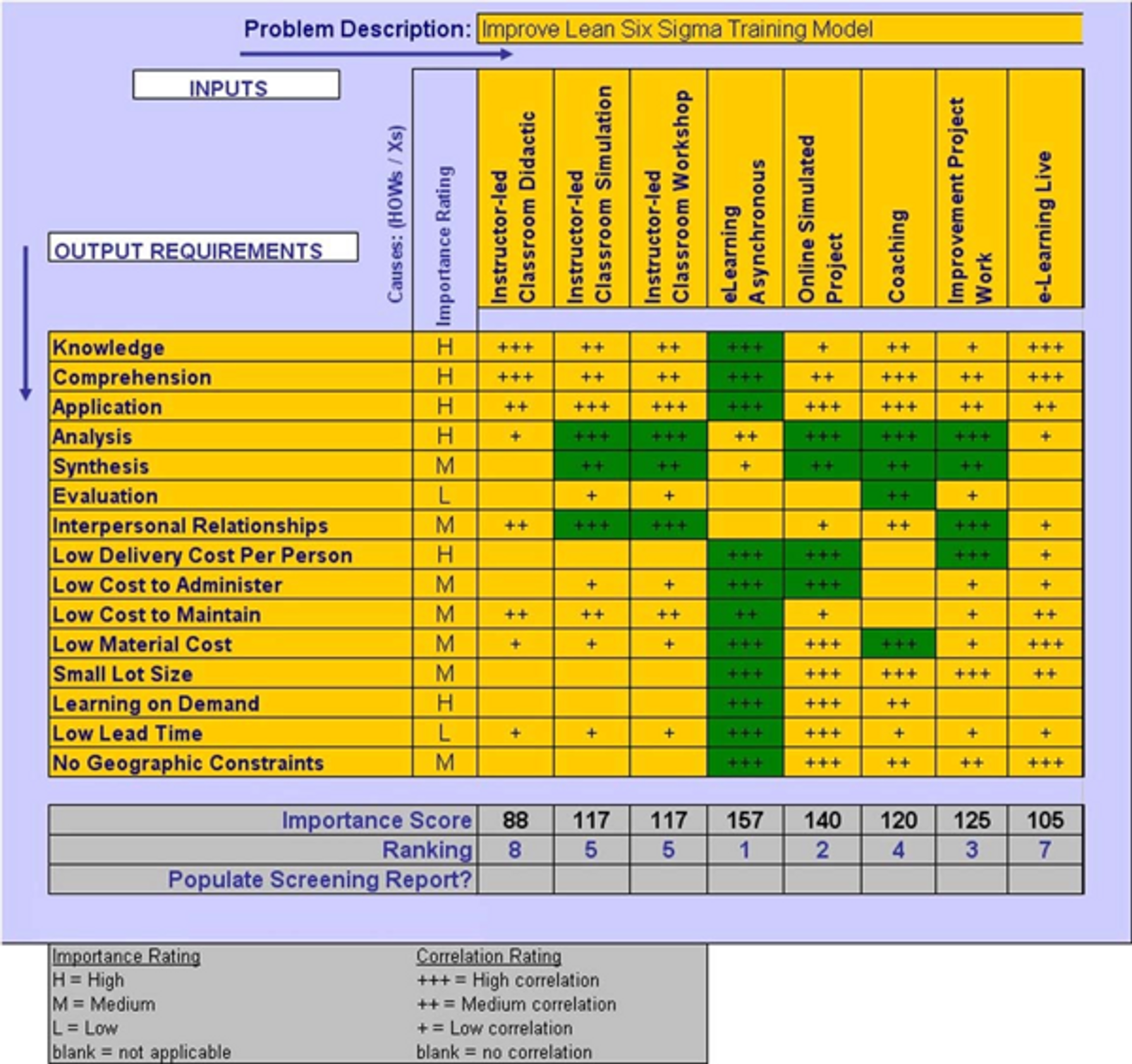

The next step is to translate these requirements, or "whats" into a learning model — the "hows" that determine the model design. To identify the linkage, we'll use a Cause & Effect Matrix, a common Lean Six Sigma tool (illustrated below). The requirements from the Tree Diagram are carried forward into the left column of the matrix, and priorities are assigned based on customer input. These are the "whats". Next, various types of training modes and methods are then listed along the top row of the matrix — the "hows", or causes, which may be used alone or in combination to accomplish the "whats", or effects. To determine which methods have the greatest impact on meeting the requirements, the strength of relationship between each mode, or "how", and each requirement, or "what" is scored (+, ++, or +++).

The overall strength of relationship across requirements is shown as an "Importance Score" at the bottom of the matrix, along with a ranking. As shown, the top‐ranked learning modes are: asynchronous e‐learning, online simulated project, actual improvement project work, one‐on‐one coaching, instructor‐led classroom workshop, and classroom simulations. A properly designed blend of these delivery modes should best meet all of the requirements.

To further inform the design, the "what‐how" combinations with the highest score and lowest cost are highlighted in green. If there is no overwhelming advantage, multiple combinations for a given requirement are highlighted.

Toward Practice‐Based Instruction

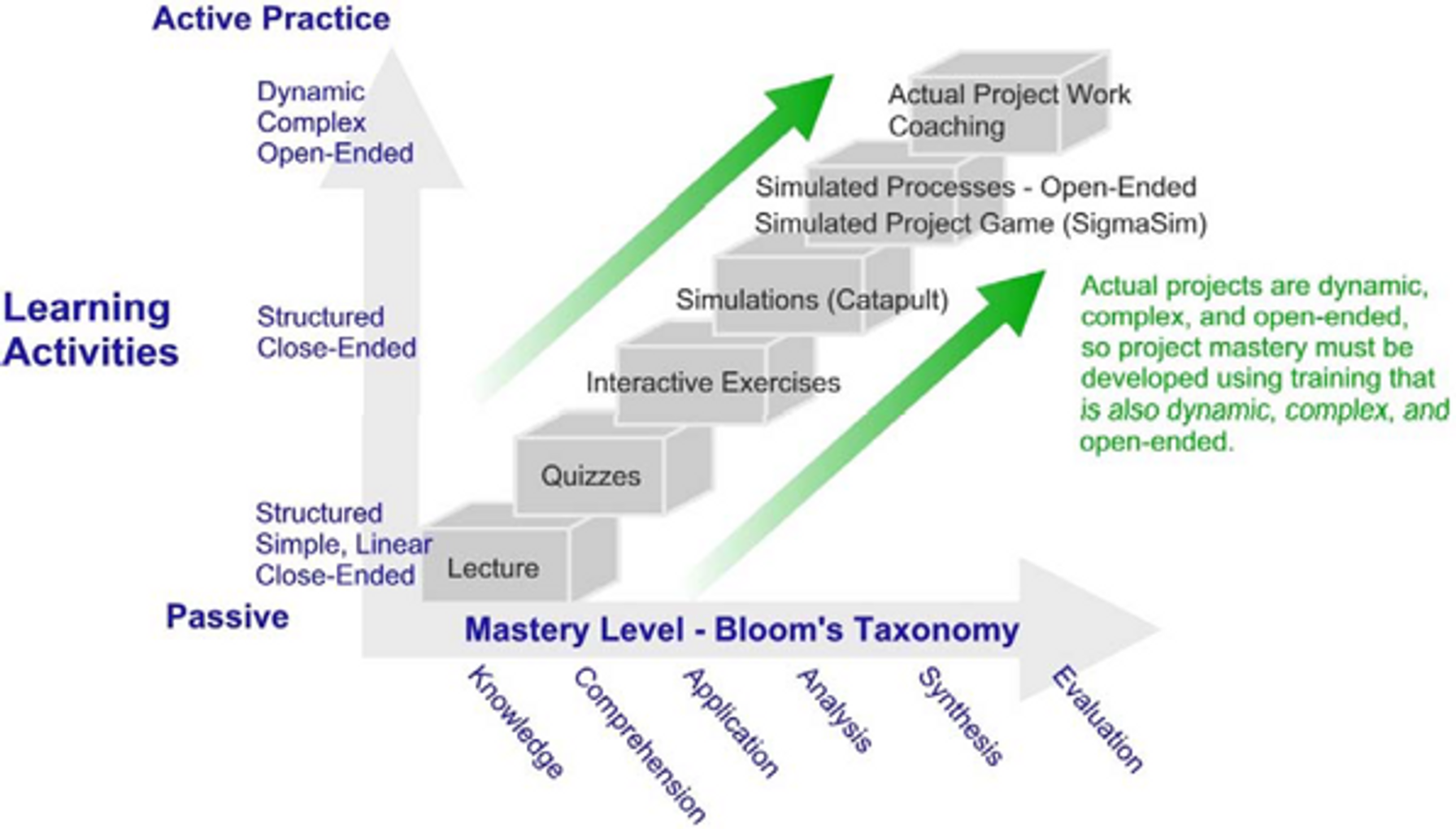

Another lens to examine the instructional design is the extent to which the learning activities are active and practice-oriented vs. passive and lecture‐based. Actual projects are dynamic and open‐ended (the possible actions and outcomes are neither pre-defined nor limited). It follows logically that to become fully prepared to manage open‐ended projects, practice in a similar environment is necessary. Lean Six Sigma tools are just too complicated to master without practice. Advancing the level of mastery upward on Bloom's Taxonomy requires a corresponding movement along the continuum of learning activities toward dynamic, complex, and open‐ended experiential learning, as illustrated below:

Learning activities may be delivered using different modes. For example, Lecture can be delivered using either a classroom or an e‐learning mode. The primary difference between modes is cost and flexibility. In fact, we could add a third axis to this model to represent the "technology" of delivery, which is really independent of activity.

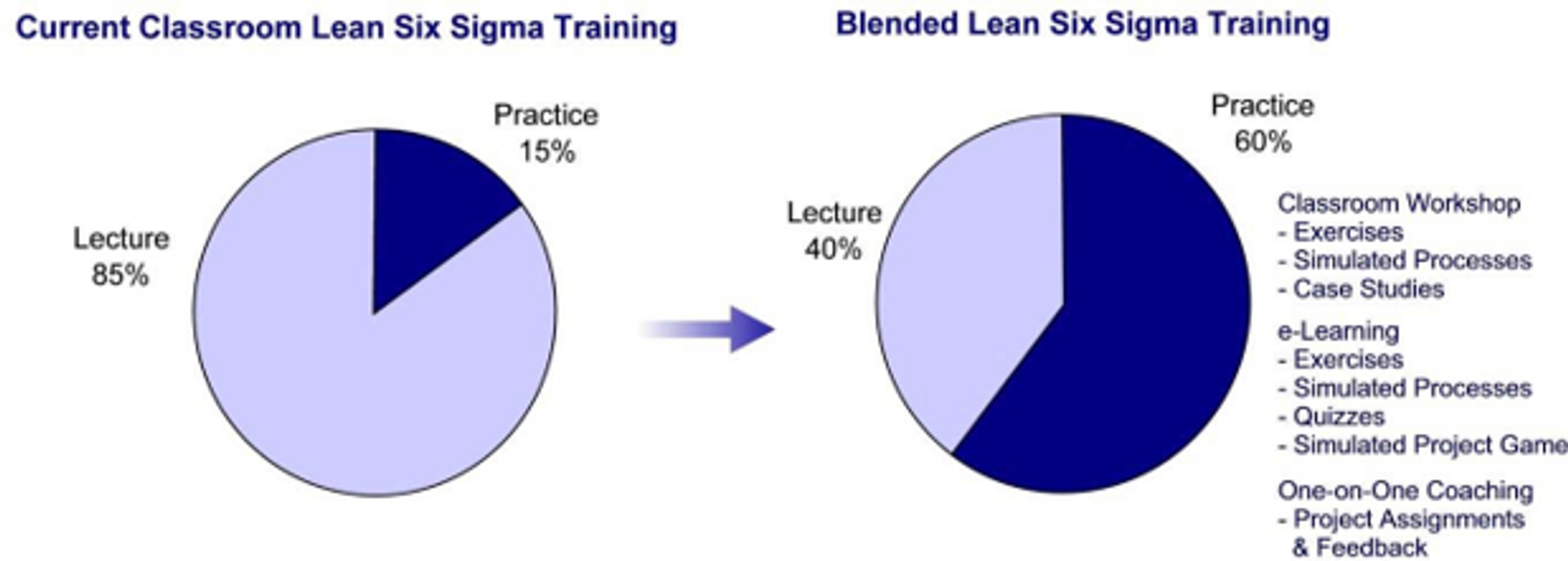

The traditional Lean Six Sigma training model is exclusively classroom-based and instructor‐led. Approximately 85% of the time is spent in lecture (telling), with 15% spent practicing (doing). A revised training model using a blend of delivery modes and activities can shift the balance significantly in favor of practice — up to 60%, as shown below:

A critical aspect of the blended model is the nature of the classroom event: the classroom experience is not just a smaller dose of the same lecture‐based instruction — instead, the character of the classroom experience is changed to a practice‐based workshop with emphasis on learning by doing rather than learning by listening. A mix of defined exercises, hands‐on simulated process improvement, and case studies are used to meet the learning objectives in a dynamic and interactive fashion.

Design of the Blended Model — Components

To use a cake‐making analogy, design of an effective blended learning model requires more than dumping the ingredients in a mixing bowl — the sequence and mix of the recipe are critical, along with the quality of the ingredients. Key components of the model are:

- Interactive eLearning with exercises, simulations, and quizzes

- Classroom Workshop with hands‐on simulations, case studies, and online simulated project game

- One‐on‐one Coaching, either in person or virtually, including project tollgates

- "Study Hall" catch‐up days with online virtual check‐ins and group discussion

Practice‐based learning is delivered virtually using advanced asynchronous e‐learning which incorporates interactive exercises, process simulations, quizzes, and a simulated DMAIC project game (Sigma Sim®). The e‐learning curriculum covers the complete body of knowledge so that it may also be used for future reference in support of project work. The classroom experience can be seen as practice to further build capability in the skills first learned and practiced online, and must be design to build on the e‐learning, not repeat basic instruction. As such, the additional classroom practice becomes a vehicle to move beyond competence to confidence — a necessary attribute of capable and successful project leadership. In our view, capability = competence x confidence.

The actual delivery design of the blended model is driven by the geography of the participants since one of the key goals is eliminate instances of travel for both cost and flexibility reasons. In the common situation where the class participants are geographically distributed, it makes economic sense to holder fewer, longer classroom events rather than frequent shorter events. In the case of Green Belt training, a prototypical model is shown below, representing a 3‐4 month total timeline.

When the geography is more centralized, such when the participants are all from a single large location, the classroom workshop can be broken into two shorter sessions, positioned after the Define work is completed, and again after Control.

Risk Analysis

By minimizing expensive face‐to‐face instruction and travel, as well as elimination of the direct costs of printing and shipping training materials, the blended model offers a minimum cost advantage of 50% (not including student travel costs). The differential of these direct costs is easy to measure. Other benefits which are harder to quantify, but present, include: reduction of administrative overhead for scheduling classes, and the benefit of on‐demand e‐learning reference resources. There is complete certainty that the blended model has a far lower cost structure. There is also complete certainty that blended models are more flexible — the e‐learning component features a lot size of one, so participants can start at any time with no lead time. So the remaining risk assessment centers on the question of effectiveness. Fortunately, an emerging body of evidence indicates that blended learning is substantially more effective than classroom training alone. In 2006, the Advanced Distributed Learning Initiative, which is funded by the DOD, conducted a Meta‐Analysis of ninety‐six research reports examining results of 26,460 people taking 208 different training courses. A summary of results is presented below:

Across all studies, the results indicated that combining classroom and Internet components was more effective than stand alone Classroom Instruction for teaching job‐relevant knowledge and skills. Blended Learning was 11% more effective than Classroom Instruction for teaching both declarative and procedural knowledge. *

Similar results were experienced by Quest Diagnostics in 2006 when the company migrated from 100% face‐to‐face classroom instruction for Black Belt training to a blended model similar to that presented above. Test results improved by 22% — consistent with the results predicted by the Meta Analysis. Subsequently, other large corporate Lean Six Sigma deployments and universities have witnessed the benefits of blended training, including: Cardinal Health, MDS, Xerox, Emerson Electric, Ohio State University and California Polytechnic University. Moving to a blended model actually decreases effectiveness risk — all available data indicate that the riskiest proposition is to continue to train people using traditional lecture‐driven classroom instruction.

The one risk that is present with blended learning models incorporating asynchronous e‐learning, is the potential for participants to either lag behind or not complete their training. Since e‐learning can be used at any time, usage can also be delayed at any time. Four structural elements can be used to mitigate this risk:

- Participants should all have an assigned coach to proactively monitor progress against a defined learning plan, facilitate project Tollgate reviews, and answer questions along the way.

- Scheduled virtual "study halls" can be employed as "catch‐up" days to ensure that participants stay on pace. Study halls would typically be scheduled every 1‐2 weeks during the e‐Learning phase, and would consist of a dedicated learning day with periodic check‐ins for anyone not keeping up to the defined learning plan. This strategy has been used effectively by Quest Diagnostics and MDS.

- The MoreSteam Learning Content Management System enables a "Nagging Feature" which automatically monitors course progress to plan, and sends reminder emails to the participant and coach at the planned 25%, 50%, 75%, and 100% course completion milestones.

- The project‐driven approach pulls learning because it is necessary to complete project work and meet project tollgates. This is a distinct difference from the practice of initiating project work after the training.

Summary

The blended learning model resolves each of the seven forms of waste present in the traditional instructor‐led classroom training model, yielding higher effectiveness at lower risk, and a dramatically lower cost structure. Blended learning has become the best‐in‐class approach to Lean Six Sigma training, and should be strongly considered by any organization contemplating a Lean Six Sigma deployment, or a re‐design of the existing training model. Lean Six Sigma can be applied to Lean Six Sigma training.

*Traci M. Sitzmann, Advanced Distributed Learning; Kurt Kraiger, Colorado State University; David W. Stewart, University of Tulsa; Robert A. Wisher, Department of Defense

Bill Hathaway

CEO

MoreSteam