The Process Capability Index (Cpk)

Definition

The Process Capability Index (Cpk) is a statistical measure used in quality control and process improvement to assess the capability of a process to produce products or services within the specification limits. It provides a quantitative assessment of how well a process meets customer or design specifications.

Both Cp (Process Capability Ratio) and Cpk are ratios and indices. The difference between the two is that Cp assumes the process is centered, so it only compares the spread to the specification range, while Cpk takes the distance from the actual center to the nearest spec.

How to Calculate Cpk

Cpk is calculated using the following formula:

Where:

Cpk = centered process capability index

Mean = Mean value

USL = upper specification limit

LSL = Lower specification limit

𝜎 = within-subgroup dispersion (standard deviation)

The components of the formula represent:

The term (𝑈𝑆𝐿−𝑚𝑒𝑎𝑛)/3𝜎 measures how many standard deviations the process mean is from the upper specification limit (USL). It indicates how well the process can meet the upper limit.

The term (𝑚𝑒𝑎𝑛−𝐿𝑆𝐿)/3𝜎 measures how many standard deviations the process mean is from the lower specification limit (LSL). It indicates how well the process can meet the lower limit.

The Cpk value is the minimum of these two values, and it reflects the worst-case scenario for the potential capability of the process. The goal is to have a Cpk value greater than 1.0 (many industries use a higher threshold of 1.33), indicating that the process is capable of producing products or services that are within specification limits. A Cpk less than 1.0 indicates that the process may not be capable of consistently meeting the specification requirements.

In summary, Cpk is a useful tool for assessing and quantifying the capability of a process to meet customer or design specifications, taking into account both the mean and variation of the process output. It helps organizations identify areas for process improvement and ensure product quality.

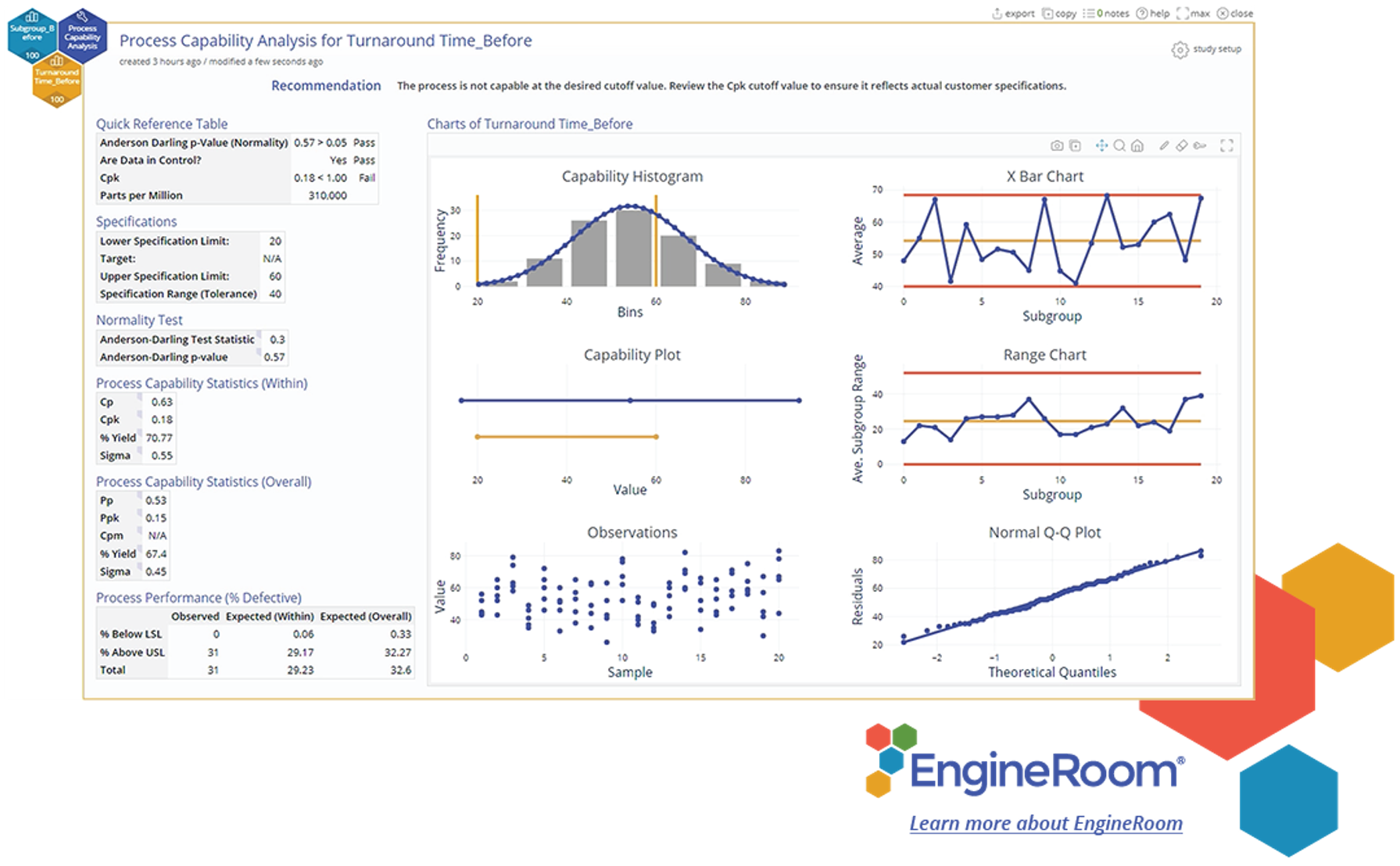

Recommendation: The process is not capable at the desired cutoff value. Review the Cpk cutoff value to ensure it reflects actual customer specifications.

EngineRoom and Cpk

Calculating Cpk by hand is not only tedious and prone-to-error, but also unnecessary! Using data analysis software like EngineRoom saves time and effort, as well as additional context around that Cpk number.

Use the Process Capability tool in EngineRoom to run the numbers. It will check that the important criteria for interpretation are correct. In other words, are the data normally-distributed and is the process in control? Then, if those pass, it will indicate whether your process is capable or not based on the Cpk number.

Over time, you can evaluate whether or not changes you’re making to your process are helping. By comparing before and after data using two Process Capability tools, you can show whether the process is becoming more capable.