Making the Case for Organized Process Improvement

November 11, 2022If you want to have a competitive edge, deploying an operational excellence program like Lean Six Sigma into your organization cannot be optional.

Ad hoc process improvement methods don't work; if you want sustained results, organized process improvement is imperative.

Lean Six Sigma has proven itself to be a valuable problem‐solving method. However, it is not an instant pudding mix.

Democracy is the worst form of government, except for all the others.

In some respects, Mr. Churchill could have been commenting about organized process improvement. For all of the problems and valid criticisms associated with organized process improvement, there is only one even worse alternative: everything else.

Is Lean Six Sigma Right for My Organization?

Here's the bottom line: Lean Six Sigma is right for every organization.

A prospective client recently asked for help making the logical case for Lean Six Sigma. Here are the major points based on our experience:

Operational excellence is not optional. In any competitive business environment, process improvement initiatives are imperative. There is no extra margin in your business to underwrite waste.

Process excellence is the most critical strategic enabler. Process excellence means closing the performance gap between customer requirements/expectations and the actual output of the organization's core processes.

Ad hoc methods don't work. If they did, your organization wouldn't have any glaring problems to fix (I assume you have at least a few, like everybody). Every operationally world‐class organization has a rigorous approach to problem‐solving and process improvement.

So If Ad Hoc Process Improvement Methods Don't Work, What's the Alternative?

Organized improvement efforts that are customer‐focused, systematic, informed by data, and supported by capable (trained) people and engaged leadership.

Or, in other words, Lean Six Sigma.

The name is irrelevant — call it whatever you want; Operational Excellence, Continuous Improvement, Process Excellence, etc. What is important is combining the following:

- Organizational structure

- Project identification

- Leadership support

- The right analytical tools

- Sound methods

- The right people

- An architecture of project management that drives critical thinking (like the DMAIC method, for example)

Learn More about MoreSteam's LSS Training Programs Here

Decades of Success Prove Lean Six Sigma's Value

Since its origins in the early '90s, the organized approach to process improvement known as Lean Six Sigma has evolved continually to adopt new practices and meet emerging challenges, including:

- The original roadmap of MAIC (Measure‐Analyze‐Improve‐Control) was amended to add Define at the front end. It's always good to start with a clear idea of what you will accomplish.

- Lean methods were explicitly merged into the approach to focus on value creation, waste, flow, and rapid problem‐solving.

- Although initially rooted in manufacturing, Lean Six Sigma became a universal process improvement methodology applied across all industries and functional areas.

- The emphasis shifted from tools to critical thinking and pragmatic problem‐solving in many circles.

- The incorporation of Agile practices has helped put a priority on speed. All too often, Lean Six Sigma projects are managed under the presumption that having tools is more important than getting things done.

- More structured alignment with strategic imperatives through Hoshin planning or similar practices has ensured that process improvement projects target problems that matter.

- The wider availability of digital training has broadened participation in meaningful problem‐solving beyond a narrow class of experts.

For these reasons, Lean Six Sigma has grown and developed over 30 years to remain relevant, practical and powerful. There are now more organizations using some form of Lean Six Sigma than ever before because it's a flexible "umbrella system" that is adaptable and effective. It's also a human system, so yes, it can be misapplied, or misrepresented, or misused, but if employed properly, it delivers.

For More Resources on Continuous Improvement Subscribe to Our Newsletter!

Recognizing the Return on Investment

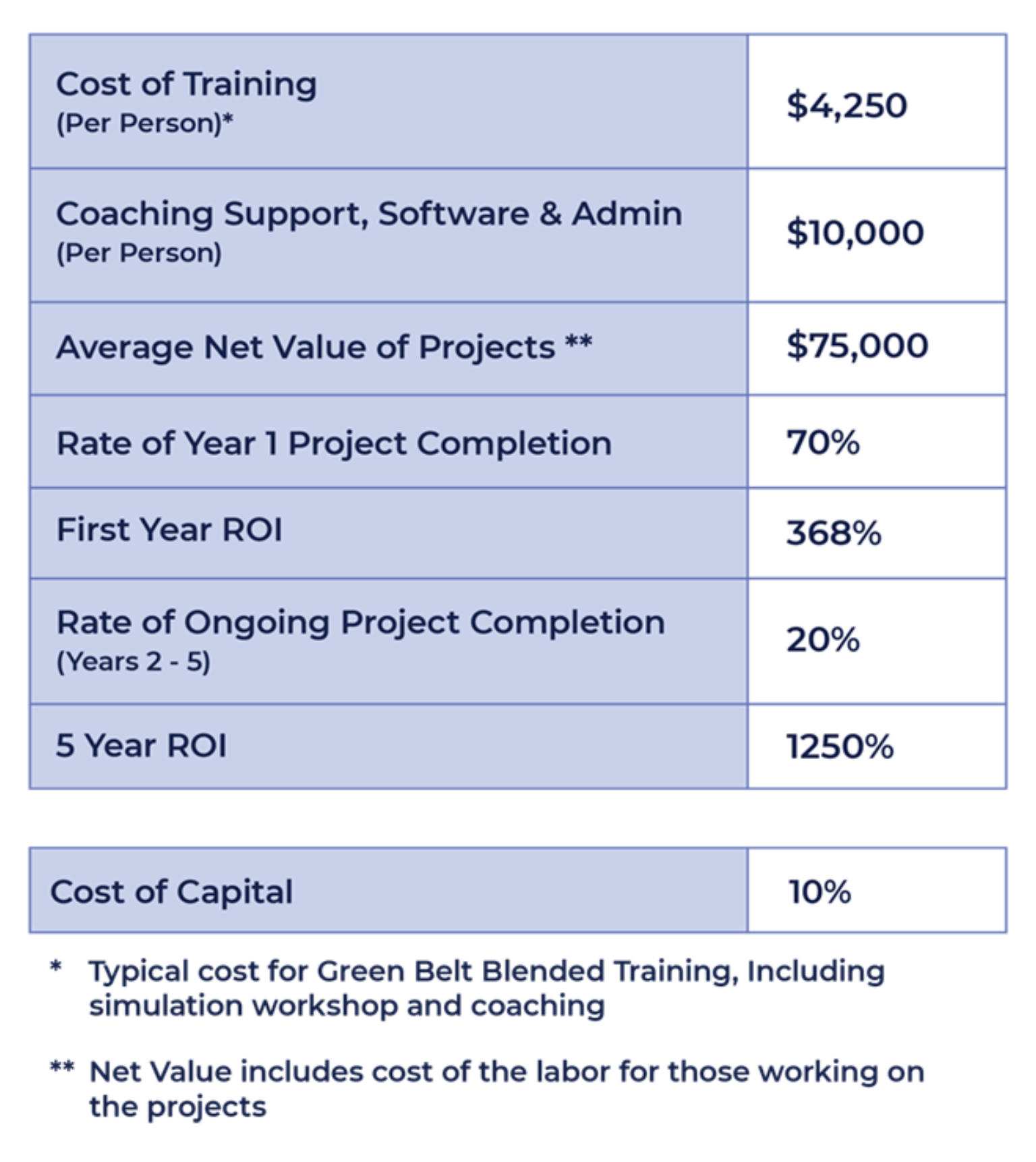

When meaningful projects are completed, organized efforts to improve process performance have a clear and compelling return on investment because the benefits far outweigh training and administration costs. The key variables that drive the ROI equation are the value of completed projects and the rate of project completion (percentage of those trained who complete a project in a given period). The cost of training and the overhead associated with managing the system are also meaningful inputs, but the benefits typically dwarf those costs.

The above example represents a typical process improvement initiative with very conservative assumptions about project value and completion.

Project completion in the years after initial training is the single most important variable impacting ROI. Suppose the system encourages trained individuals to lead and execute projects to do the work to solve fundamental problems over many years rather than a "one and done" approach driven by certification. In that case, the ROI is much higher.

The most crucial mission is to maintain the ongoing linkage between evolving strategic initiatives and the project work necessary to close performance gaps. Building human capability to execute that mission is the heartbeat of any organized process improvement system. To my knowledge, these things have never happened by accident.

But the Last Time We Tried, It Failed.

Keep the following knowledge in mind when returning to the drawing board to yield the results that you want:

Real change takes time. Businesses cannot achieve sustained operational excellence through band‐aid fixes but rather by resolving the root cause or causes of process problems.

Process improvement methods take expertise. Finding and fixing the root cause of process problems in a cross‐functional value stream (or any value stream, for that matter) is not child's play — it requires a method. It's also not a part‐time job. Solving complex problems requires experts using sound data‐driven methods, coaching, leadership support, and dedicated and sustained effort.

Structured critical thinking is more important than tools. Lean methods are great for getting the wider organization involved in simple front‐line problem‐solving. However, some problems are complex and require deeper data analysis to identify root causes. Lean and Six Sigma methods are complementary when applied appropriately to solve the issues at hand, and there is no benefit in arguing about which approach is best.

Avoid Common Organized Process Improvement Problems

Even with all of the evidence proving LSS' worth, it can feel intimidating to implement a strategic operational excellence initiative across your entire organization.

Looking back on our experiences working with clients over the last 18 years, we've collected a short list of tips on how to avoid common issues found in process improvement deployments:

You cannot delegate leadership

Successful and durable process improvement efforts depend on senior leadership engagement. Leaders should be active teachers. "Engaged" means process improvement activities are on their calendars and "to‐do" lists — not an initiative assigned to others.

This deployment is not an "organic" exercise at the beginning

A certain amount of senior leader energy is required to get things started. It may seem counterintuitive when your goal is to build an empowered workforce. But you need a solid directive to reorient people to enterprise process improvement.

Most important projects will cross functional boundaries, so leadership must enforce value‐stream thinking that puts customers ahead of departmental priorities.

The "M" in DMAIC does not stand for 'Months'

Results eat methods for breakfast. Don't let people get hung up on playing with tools at the expense of getting things done. Practicality should rule. Remember that a highly accurate and precise measure of screwed up is still screwed up.

Don't take on projects that have massive scope

It is better to execute a series of smaller, tightly‐focused projects that could actually get done than to immediately take on your organization's "big picture" vision. Just make sure that those smaller projects are closely linked to strategic imperatives and solve problems that matter.

Remember the "3APs"

Beware of Gembaphobia (the fear of going to where the work is actually performed). Challenging problems aren't solved in a conference room. Go to the actual place (Gemba) where the work is done, observe the actual process as it is performed, and talk to the actual people who perform it.

Don't pick the most available people to become project leaders

Sometimes there's a reason why people are available for an assignment, and it's not because they get things done. Make the functional leaders cough up their best people to become Black Belts and Green Belts. Employees with the right attitudes and people skills will get more done than those with a mastery of advanced technical methods. Developing capable problem solvers is also an apprenticeship process, requiring guided experience to become effective; don't neglect the idea of coaching.

Avoid establishing a "Caste System" or "Expert Culture" where only experts can solve problems

Everyone can use these tools and this thinking in their daily work. Waiting for an "expert" can become a convenient excuse to avoid deployment. Most improvement happens with simple tools, and the discipline to recognize problems from a customer perspective and address them head‐on is more critical than technical skills.

Don't operate in secret

Over‐communicate to offset the natural fear of change and suspicion. The most durable process improvement initiatives involve leaders actively communicating the benefits to the broader organization as they unfold. Without internal marketing, the people involved in process improvement can become a target for short‐term cost reduction.

Don't forget middle management

The layer of clay in‐between senior leadership and front‐line leaders requires extra attention to penetrate. Middle managers must get on board for the approach to have legs. If leaders lead, middle managers will follow.

Don't train without projects!

It's a total waste of time and money to train without projects. Don't over‐train, in advance, in batches. Try to pull training as needed to support the work that needs to be done.

That work should flow from the organization's Strategic Imperatives to be successful. To achieve the "plan to win," projects should target the performance gaps that must be closed.

The Bottom Line

You need to have organized process improvement, and you need to build a culture of problem‐solvers. Don't get hung up on the terms — continuous improvement, process improvement, operational excellence, lean six sigma — it's all the same. What matters is strengthening the problem‐solving muscle in the organization and oiling the organized system in which we do that problem‐solving work.

Just like accounting methods, process improvement methods work when properly applied. But they can be improperly applied. The failure of Enron is not an indictment of accounting, only a failure of leadership.

As much as your organization wants to see significant improvements tomorrow, Lean Six Sigma requires proper execution.

There is no instant pudding.

That's my 2 cents,

— Bill Hathaway

CEO • MoreSteam

MoreSteam is the brainchild of Bill Hathaway. Prior to founding MoreSteam in 2000, Bill spent 13 years in manufacturing, quality and operations management. After 10 years at Ford Motor Co., Hathaway then held executive level operations positions with Raytheon at Amana Home Appliances, and with Mansfield Plumbing Products.

Bill earned an undergraduate finance degree from the University of Notre Dame and graduate degree in business finance and operations from Northwestern University's Kellogg Graduate School of Management.