Lean Six Sigma Nutrition

August 3, 2021If there were any doubt that summer is in full swing in the northern hemisphere, I collected this evidence a week ago. The Human Cannon Ball attraction is once again traveling the land to amuse and delight. For those of you who are using Failure Mode & Effects Analysis (FMEA) for risk evaluation, this might be a good case study for training purposes, assuming that there might be a few things that could go wrong.

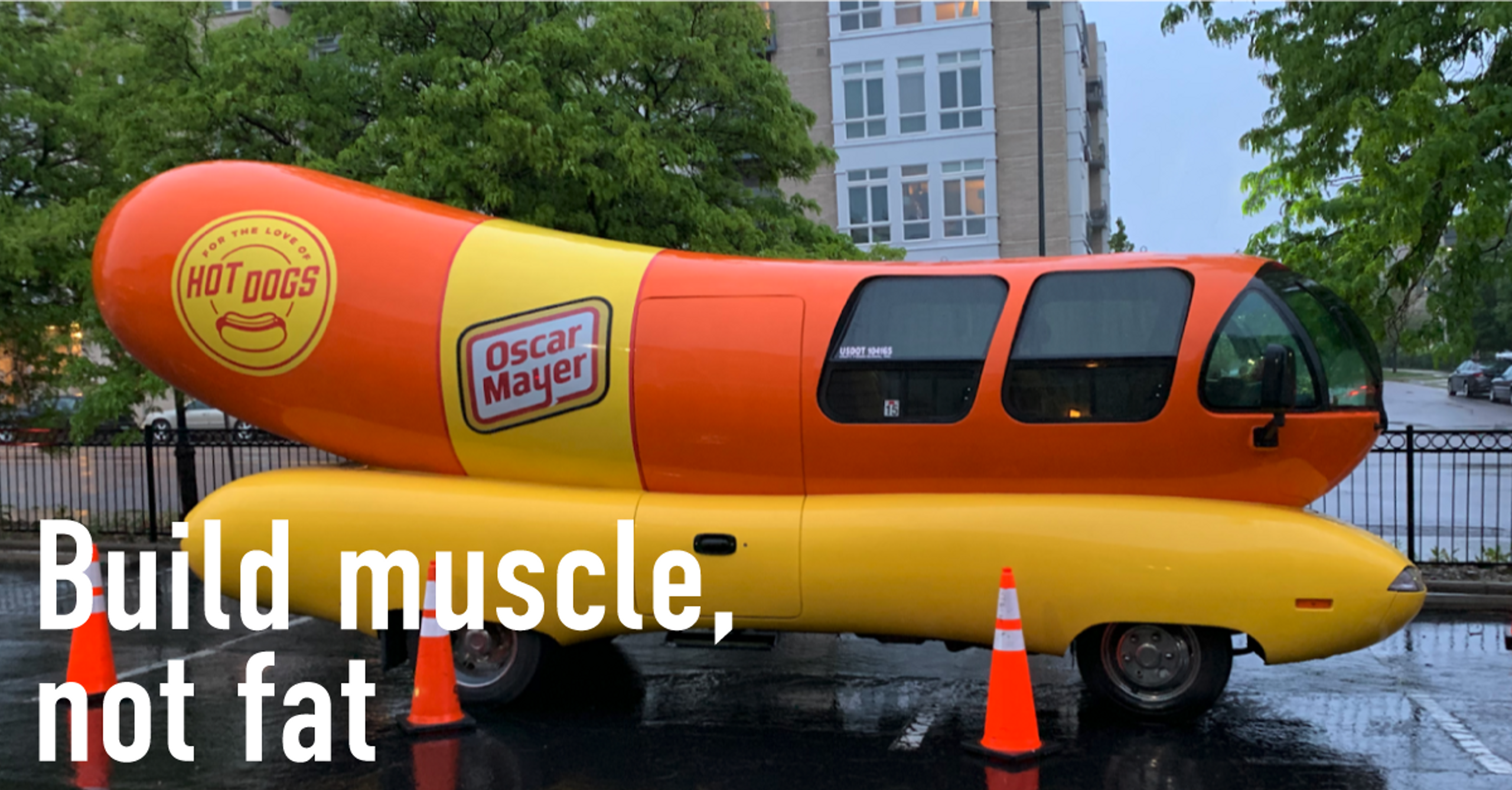

Further evidence of summer fun presented itself in the parking lot of a hotel where I was staying recently in Denver - the Oscar Mayer Wienermobile! Why doesn't everyone have vehicles like this? And how could road rage exist if everyone were driving such a silly machine?

My latest experience with this giant hot dog leads into the real subject of this piece: nutrition. Traveling during the summer is a non-stop assault on good judgement, with constant alluring pleas to opt for convenience and comfort at the expense of healthy eating. All of us are hardwired to like sugar, fat, and salt, and I know I could be happy on a diet of french fries, pizza, ice cream, and beer. Fast food is cheap and convenient, especially when traveling, but where does it lead? What about nutrition? Let's take a closer look at french fries.

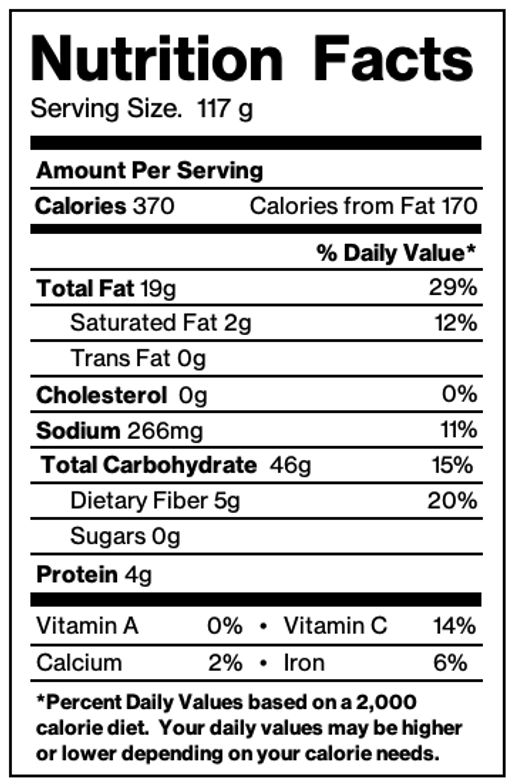

As shown by this nutrition label, a medium serving of french fries provides 29% of the daily recommended intake of fat, 11% of the salt budget, and 15% of the carbohydrate recommendation. That's tasty, and enticing, but not exactly the formula for building muscle. If you were preparing for physical competition in some sport, or just for a long and healthy life, your nutrition plan would not be centered on french fries and fast food if you had serious hopes of success.

The subject of competition brings to mind a ribbon that I found while sorting through a box of old stuff during the pandemic: my first "Yellow Belt," from a field day in elementary school. Somehow I earned 4th place in an unremembered race or challenge, and somehow fourth place was good enough to justify a ribbon! It's sadly similar to some of the Lean Six Sigma certifications that are being handed out, pretty much just for showing up and eating donuts.

But there's a serious disconnect between awards for "just showing up" and the real world of serious performance requirements that most of us live in. In business or operational competition, disciplined preparation is just as important as training for physical sports contests and mental nutrition matters.

Like a summer family trip with a car full of hungry kids, there are demands to get things done quickly, conveniently, and at little expense. Within those constraints, training can become a drive-thru experience, with very little real nutrition.

We've seen Lean Six Sigma "green belt" or even "black belt" courses a few days in length, with a long list of topics in the curriculum, but little time spent on any of the subjects, and no practice (practice is akin to protein in my mind). It would be like selling food that is "fortified" with 100 vitamins, but with only a trace amount of each. Without a nutrition label, it's difficult to know about the real ingredients.

So, What to Do? Here Are 5 Concrete Actions to Make Sure Your Training is Nutritious

- Teach the right things. Compare the topics in the proposed curriculum to the ASQ Lean Six Sigma Body of Knowledge (BOK) for Green Belt and Black Belt. In my experience, the ASQ Black Belt is well aligned with the curriculums used by organizations with durable and successful process improvement initiatives. The ASQ Green Belt BOK is more advanced than the set of tools and methods that are actually used, particularly for organizations in service or transactional businesses, but it's still a good place to start. It's important to modify the curriculum purposefully to align the training with what your people actually need to be able to do.

- Look at the depth of the curriculum. If your people need to master complex skills, they will need more than a quick trip through the drive-thru. I looked at a commercially available green belt course a couple of months ago that listed Measurement System Analysis in the curriculum, but devoted only a few minutes to the lesson. A popular social media platform for business offers a green belt course that has less than 2 hours of content! That's like food with only a trace amount of a key vitamin. It's box-checking rather than capability-building.

- Review the training for yourself. Actually look at it. It takes time, but it's too important of a decision to skip the test drive (and you'd be surprised how many people don't look for themselves). Check out the user interface, evaluate the design, challenge the content, experience the different media, and see what kind of interactions are present.

- Check references. Talk to the corporate leaders who have used the training successfully to train large numbers of people.

- Ask about the proportion of training time spent practicing. Effective training in this field requires LOTS of practice. At MoreSteam, we target a minimum of 50% of training time spent in practice activities, including high-fidelity simulations. Watching videos is the most passive approach possible, and recordings of talking heads should be a red flag.

You can rely on MoreSteam for a performance-oriented diet that is naturally high in protein and all essential nutrients, with no added sugar, zero trans fats, and no artificial ingredients.

That's my 2 cents,

Bill Hathaway

Field Day Fourth Place Ribbon-Holder

CEO • MoreSteam

MoreSteam is the brainchild of Bill Hathaway. Prior to founding MoreSteam in 2000, Bill spent 13 years in manufacturing, quality and operations management. After 10 years at Ford Motor Co., Hathaway then held executive level operations positions with Raytheon at Amana Home Appliances, and with Mansfield Plumbing Products.

Bill earned an undergraduate finance degree from the University of Notre Dame and graduate degree in business finance and operations from Northwestern University's Kellogg Graduate School of Management.