Balancing Batches

Balancing Batches: Ensure you maintain enough stock to support the demand when your process has a common resource.

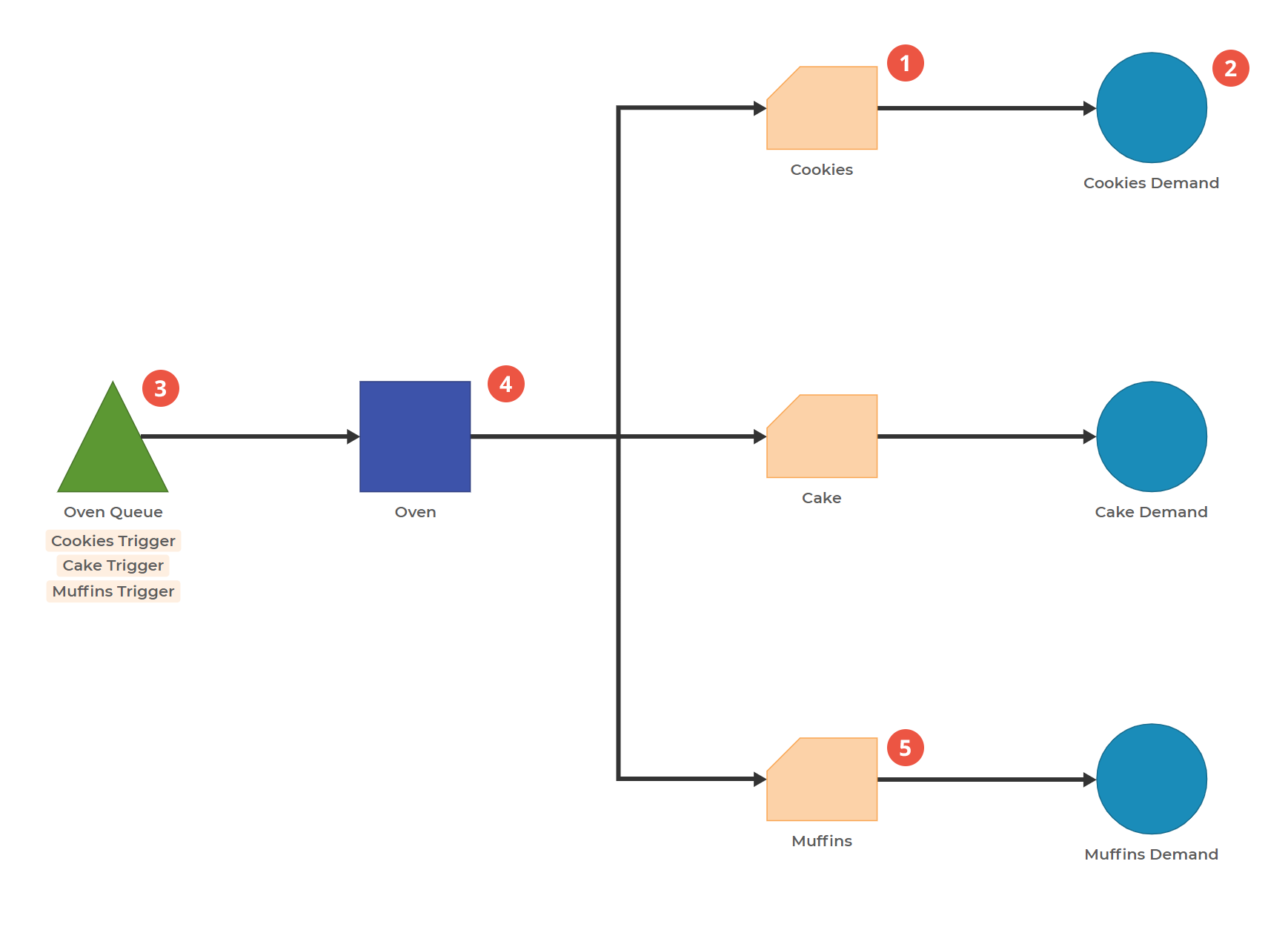

0. This model contains three items — Cookies, Cake, and Muffins.

1. Set the Initial On Hand. Each of the three Replenishment Pull blocks starts with a certain number of Cookies, Cake, and Muffins respectively. As baked goods are bought, new cookies, cakes, and muffins need to be made in order to re-up the supply. When this block hits a specific number of items left, it will trigger a new batch to start. There is also another parameter that determines the number of baked goods that will be in the new batch.

2. Create Demand. Each type of item has a unique demand. When the Demand Block is at the end of the process, it acts in Pull Mode.

3. Trigger a new batch when supply gets low. Based on the settings in the Replenishment Pull block, a new batch of Cookies, Cakes, or Muffins will be created in this Oven Queue block.

4. Process the batch in the oven. Because this is a batch, multiple items are considered together. There is a distinction here to use the Setup Time Distribution as the time to cook the batch rather than the Processing Time Distribution - the Setup Time will use that one time for the full batch, while the Processing Time would calculate a time for each item in the batch.

5. Restock the items. When the items leave the oven, they are restocked in the appropriate Replenishment Pull block. Here, the batches are "unbatched," leaving you with individual items for consumption.

This model enables you to experiment with the batch sizes that are being requested from the upstream process. Bigger batches will mean more idle time in the replenishment process and a higher average inventory. At some point, smaller batches will cause overutilization of the Activity block, and a backlog will form, leading to stockouts.

Was this helpful?