Fixtures with Parts

Fixtures with Parts. When certain items are used consistently in a process, return those items to use again.

*Note that a 'fixture' is anything that WIP mounts to or is carried in. Like an engine stand, rolling table, or mold for a boat hull, for example.

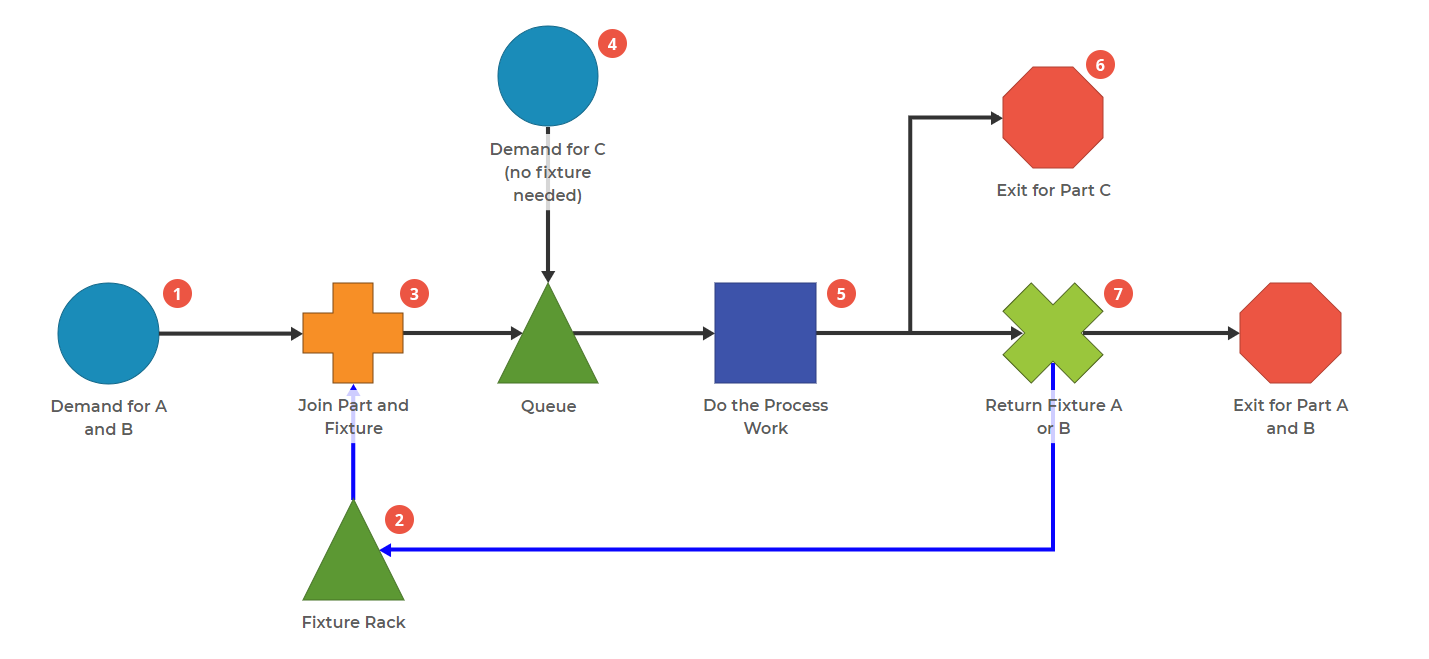

1. Create Demand for Part A and Part B. Part A and Part B are separate products with their own demand. A and B need particular fixtures (Fixture A and Fixture B) to be manufactured.

2. Stock the Fixture Rack. Only one fixture per product is available in this process. To model this, add "Initial on Hand" for each Fixture (in this case, just 1). It's also important to turn off "Allow All Items," which only allows Fixtures to return to this block.

3. Join Part and Fixture together. "Using" the fixture is as simple as joining the Fixture with the associated Item (in a new compound item called "Order A" or "Order B"). This action simulates the fixture's use, preventing its use to complete other orders.

4. Add a Third Item to the Line. Part C doesn't need a fixture, so this should be modeled after the other items have been joined with their fixtures.

5. Uniquely process each item type. Each item type has unique parameters in the manufacturing process.

6. Route the end of the process for Part C. This Exit Block only allows Part C items.

7. Split the Fixture from the Part and Send the Fixture Back. This block removes the Fixture from the Part, and since the "Fixture Rack" only accepts Fixtures, the "Fixture Item" will loop back around. The Exit block only accepts Part A and B, so those will end up there.

By limiting the number of a specific item and reusing it, this example models the use of any machinery or tools needed to craft a given item. This process is helpful when showing dies used in die cutting or pans used in baking.

Was this helpful?