Optimizing Ordering

Optimizing Ordering: Testing two fast-food processes simultaneously and observing how they respond to the same demand.

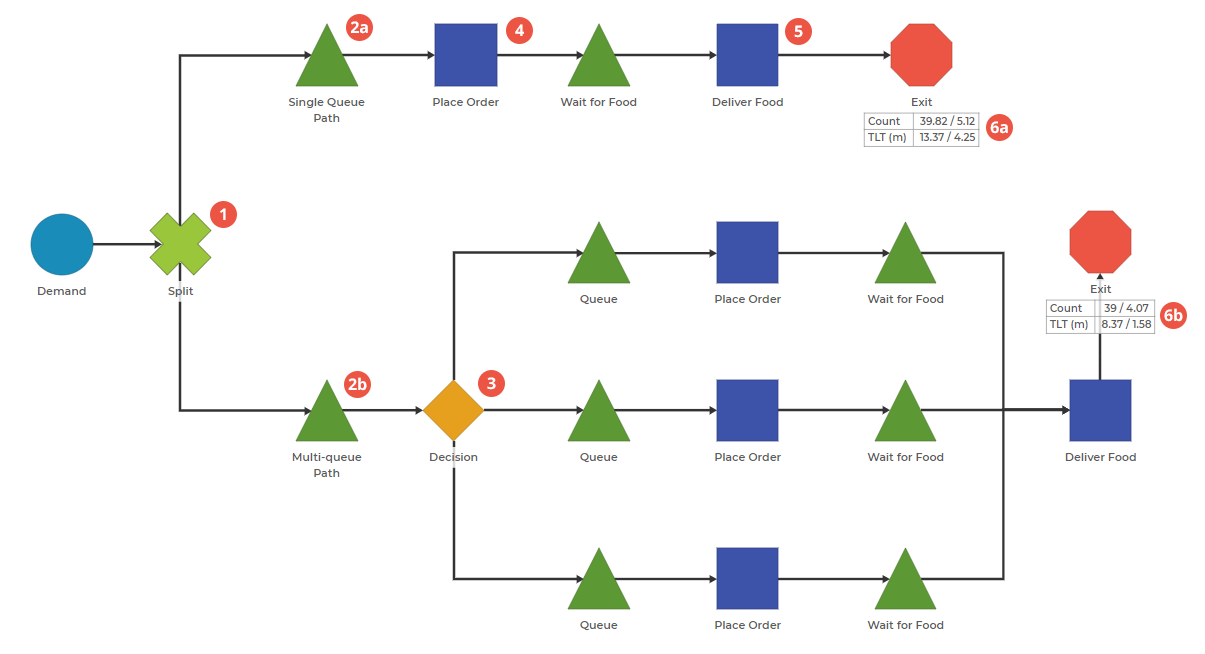

0. This model contains 3 item types: Demand, SingleQueue, and MultiQueue. The Demand item type is made up of one SingleQueue and one MultiQueue.

1. Split the Demand Item. The Demand item type is generated in the Demand Block and then split in this Split Block. This ensures that both process options have the exact same demand.

2. Direct the Flow of SingleQueue and MultiQueue. The Single Queue Path (2a) accepts only SingleQueue item types (Allow All Items is turned off) while Multi-queue Path (2b) allows only MultiQueue item types.

3. Choose Path Based on Shortest Line. This Decision Block is set to "Route based on Shortest Line," which will look ahead to see which connected Queue Block has the fewest items when the new item arrives.

4. Place Order Has Identical Processing Times. Each of the Place Order blocks has the exact same distribution of processing time.

5. Deliver Food Has Identical Processing Times. Both Deliver Food blocks have the same processing times.

6. Compare the Count and Total Lead Time (TLT) of Both Processes. Notice how the count of items making it through is roughly the same for both processes, but the Total Lead Time, or the amount of time through the whole process, is significantly lower for the multi-queue process (6b).

When running a process simulation with variation, you might not get the same results each time. Therefore, you may be interested in running a model multiple times to get an accurate picture of your output metrics. Process Playground can run multiple runs at once and then give the results in the form of mean/standard deviation.

This model utilizes this cross-run view to understand that even when the steps take the same time with a shared resource, the multiple-line option does reduce the overall amount of time in the process.

Was this helpful?