Scheduling at a Detail Shop

Scheduling at a Detail Shop: Developing the best balance between product (we'll refer to them as 'services' in this model for clarity purposes) mix and resource allocation.

00. There are 9 item types (services) in this model: Exterior Wash, Interior Cleaning, Headlight Restoration, Leather Cleaning and Conditioning, Waxing, Paint Correction, Odor Removal, Pet Hair Removal, and Stain Removal. Phew!

0. Model one day of work. We set the model run time to 540 minutes (9 work hours * 60 minutes). Adjust as needed.

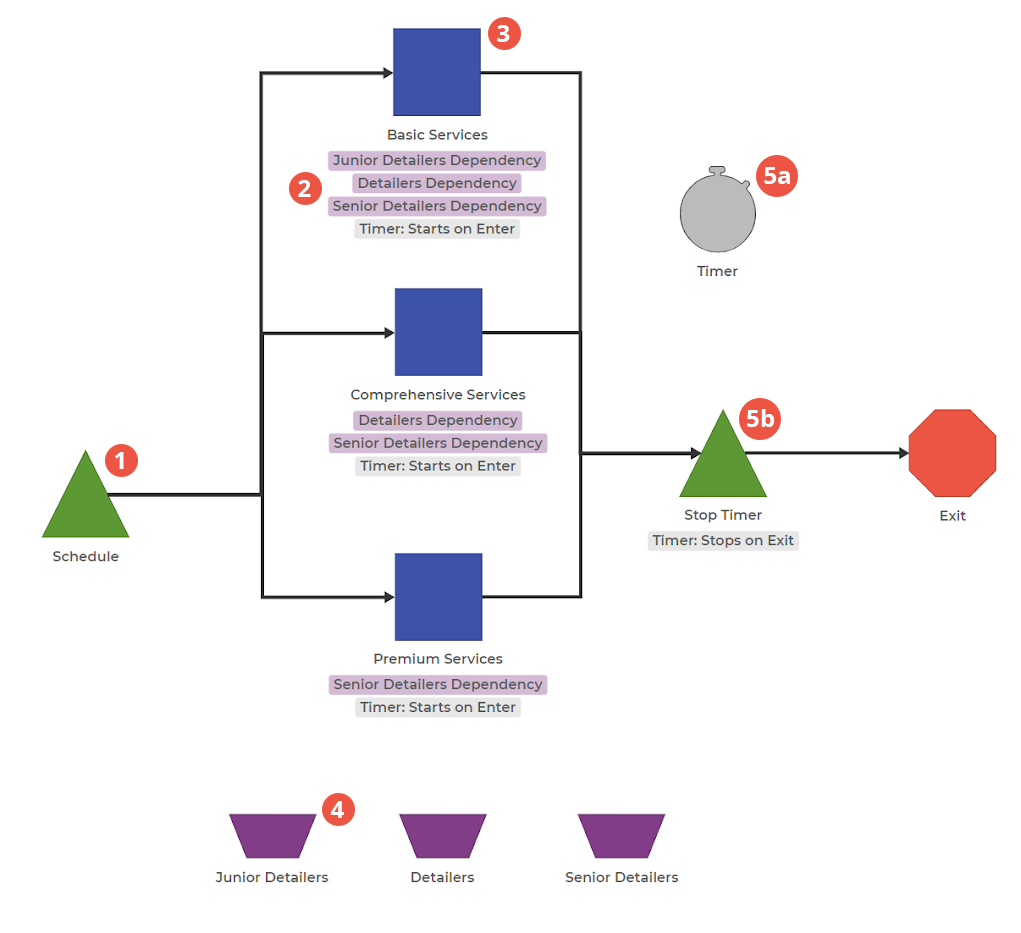

1. Set up the "schedule" of item types. Add each item type to this Queue Block and set the "Initial On Hand" parameter to the average number you'd see daily. No need to add randomization since the goal is to complete all work during the run time. Note: If randomization does matter, see the note at the end.

2. Separate products by who can do them. This suggestion is just one way that you can model this shop. Create one Activity Block per staff type, turn off "Allow All Items," and add each service (3 per Activity Block) and the time distribution to complete it. Then, use the Resource Block to "attach" a particular resource type to that activity.

3. Allow "One" Staff Member to do Basic Services. Once you add multiple Resources to an Activity Block, a new parameter appears to specify if all or one resource is needed. Select "One" and then set the priority of which Resource gets pulled in when making a choice. Repeat this with the "Comprehensive Services" block.

4. Set the number of Staff and their priorities. In each Resource Block, set the number of available staff members. The number of staff can be flexible throughout the simulation run. In addition, for resources assigned to multiple blocks, set their priority for the order of completion. Important note: Go back to the Activity Blocks and check that the number of Servers Available is greater than or equal to the total number of staff available to work on that item.

5. Time how long each service takes for further analysis. The Timer block (5a) adds a time value to each item, which you can see in the Item Report (accessed from the toolbar). In this case, we're noting the specific amount of time it took to complete the Activity of the item. The Timer starts when the item enters the Activity Block and stops when the item exits the Stop Timer Queue Block (5b).

This model assumes that the goal is to complete all tasks, not the order in which they must be completed. Experiment with this model by considering how you might adjust the product mix (the number of each product that gets scheduled for the day) and the resource allocation (the number of detailers available over the course of a day) to ensure that all of the tasks reach the end.

Additionally, consider other ways of modeling this shop:

- Randomize the order by using a Decision Block with Queue Blocks.

- Adjust who works on which services.

- Simplify the product mix by grouping them by the time each takes.

- Add additional demand by using a Demand Block.

Was this helpful?