Mixed Model Product Line

Mixed Model Product Line. This model highlights using multiple items on a single line. While the model itself is simple, we will discuss how to interact with multiple item types in this situation.

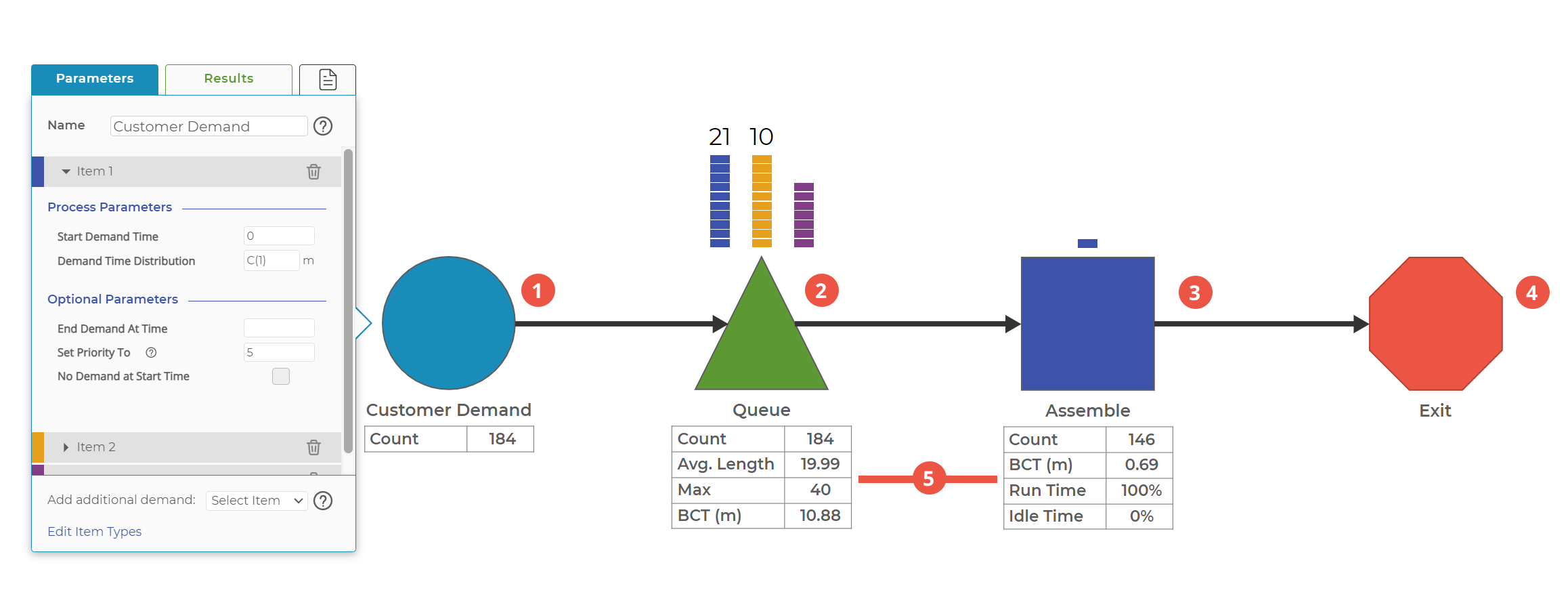

0. There are three item types in the model: Item 1, Item 2, and Item 3.

1. Add the three items to the Demand Block. By doing this, you can have a single block to generate all of your items for the model. Each item has its own parameters, so you can individually adjust the demand rate and the timeframe during which the item is created.

2. All items flow into the Queue, waiting to be Assembled. This step may represent a physical queue, or it could be how the demand was scheduled to enter the process. Since, in this model, we're not using Priorities, the items will leave the Queue first in, first out.

3. Assemble the items, each with their own unique times. The "Assemble" block in this model is a simple representation of the assembly of a part; your model may need more steps. This block can also set parameters based on specific item types. Each item type may take a different distribution of time to assemble, and you can set that in this block.

4. Items Exit. If you add each item to this Exit Block, you can get statistics for each item type individually.

5. Block Statistics. These Data Blocks are created from the Results Tab in the popover. Use these for easy views of your statistics without having to double-click into the popover every time.

This simple model highlights one way of creating a "Mixed Model" product line. Of course, you could also use multiple Demand Blocks that feed into a single line, but adding items to a single Demand Block is just as effective.

Was this helpful?