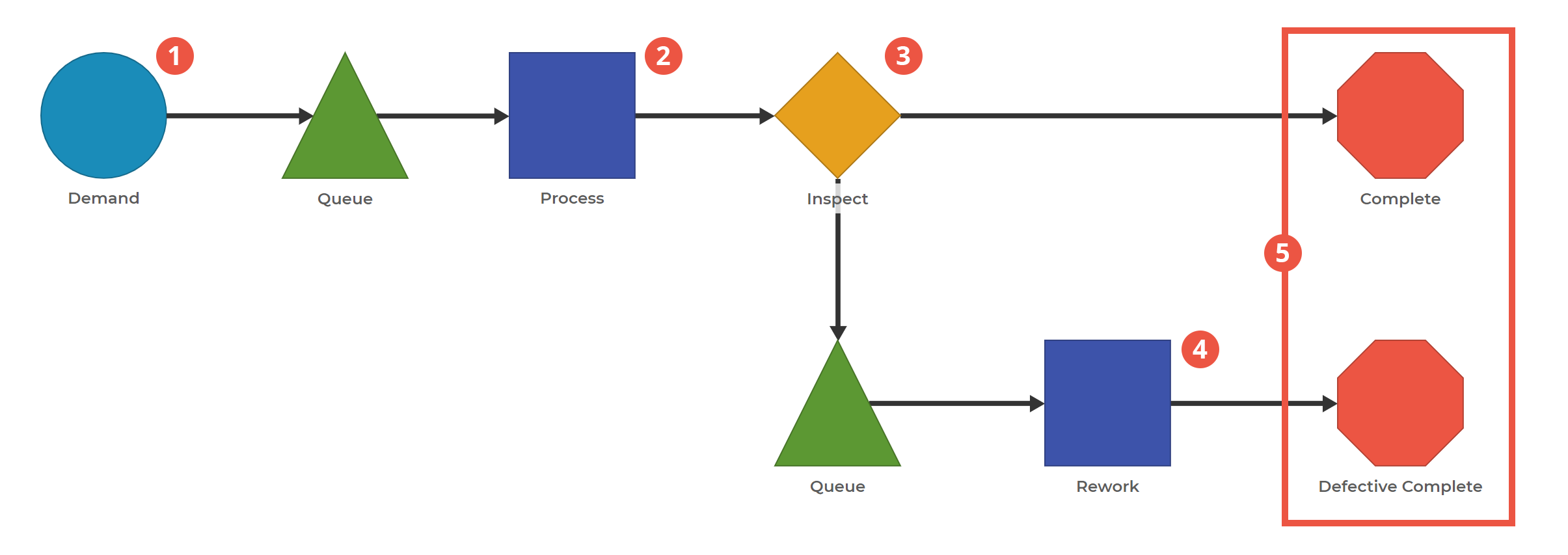

Modeling Defects

Defects: This process highlights one way of accounting for defects and rework.

0. This model has one item: Item 1

1. Set the Demand. Create Item 1s where the time between each item is set by a specific distribution. Item 1 can represent any generic "thing" that moves through a process: a widget, a form, or an email.

2. Work on an Item in an Activity Block. This block represents the time spent working on the item, whether it's assembly, filling out a form, or responding to an email.

3. Set the rate of defects in the Decision Block. Account for a certain rate of defects by setting this block to Route based on Probability. When experimenting with how defects affect your process, adjust the percentage to be lower to show how a focus on quality improves throughput and lead times.

4. Define the Rework process for Defects. When an item is routed as a defect, you can decide whether it gets processed as scrap (where the process would simply end) or create a series of steps where the defect can be corrected and eventually considered complete. We've kept it simple in this case with just one "Rework" activity.

5. End the process. We have created two different Exit Blocks to highlight the results at the end, particularly the difference in lead time.

Defects, one of the 8 Wastes, can be modeled using Process Playground to demonstrate their effects on the process. This can be a simple teaching model or used to illustrate where the focus on quality matters most and get buy-in for project work.

Was this helpful?