Selling Custom Pizzas

Selling Custom Pizzas and Slices. Managing the Kitchen flow based on customer demand is essential to a restaurant's success. This week, we introduce a custom pizza order, which "pushes" demand into the process rather than pulling demand (we saw this in detail last week).

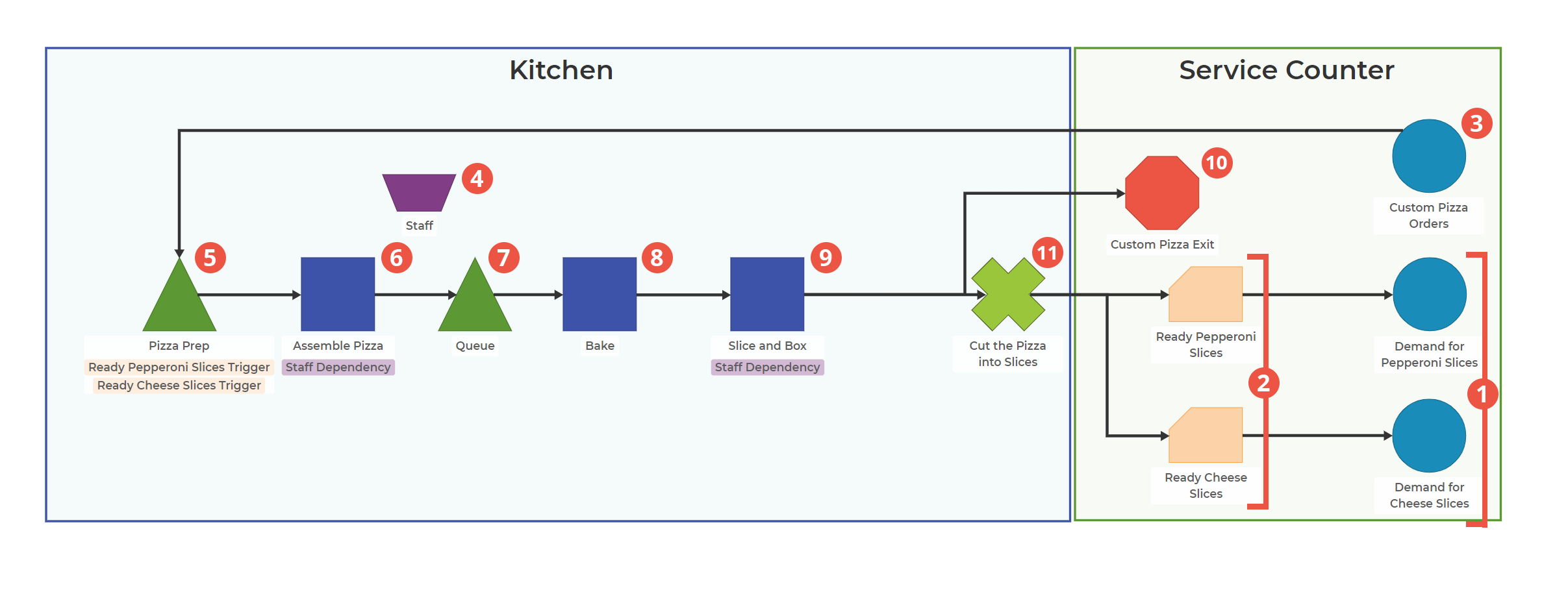

0. This model has 5 items: Pepperoni Slice, Pepperoni Pizza (made of 8 Pepperoni Slices), Cheese Slice, Cheese Pizza (made of 8 Cheese Slices), and Custom Pizza.

1. Customers can purchase individual Pepperoni and Cheese Slices. These Demand Blocks simulate the demand for those items.

2. Store the available Pepperoni and Cheese Slices. The demand for pizza slices is satisfied by having a ready inventory of prepared slices, probably under a heat lamp. These Pull Blocks hold the available number of slices and trigger the start of the process to cook whole pizzas when stock runs low.

3. Model orders for custom pizzas. This Demand Block represents a customer ordering their own full pizza. In this case, rather than satisfying that demand with ready-made options that need to be restocked, we are pushing that demand into the system and starting the process of creating that new item.

4. Staff the Kitchen. This Resource Block represents the people who complete the Kitchen activities. This includes assembling pizzas, slicing them, and boxing them up. Notice how those steps have a Staff Dependency label.

5. The start of the cooking process is Pizza Prep. When Demand is triggered either by a Push from the Demand Block or a triggered item from the Pull Block the relevant Pizza item will begin its process in Pizza Prep, where it will wait until a Staff member is available to get started.

6. Assemble Pizza. When staff is available, they will assemble the pizza, which will take varying times depending on whether it's Cheese, Pepperoni, or Custom.

7. Wait for Oven. If the oven is already at capacity, hold some uncooked pizzas in Queue.

8. Bake the Pizza. The oven has limited capacity, so the Servers Available parameter in this block is set to 4. Each pizza type has different cook times.

9. Cut and Box the Pizza. This consistent amount of time should be included in each Pizza order.

10. Deliver custom pizzas. With Allow All Items turned off, this Exit Block will collect all of the Custom Pizzas that get delivered to the customers.

11. Cut the Pizza into Slices. With Allow All Items turned off, this Split Block will turn Cheese or Pepperoni Pizzas into Cheese or Pepperoni Slices. These 8 slices can now be used to restock the Pull Blocks for customers to purchase.

Brian says: "In a model like this, we can test theoretical changes to our restaurant before committing resources. This is crucial in optimizing efficiency and operations, especially in small kitchens with tight budgets. Simulating scenarios and adjusting parameters like staffing and oven usage can identify bottlenecks and save on utility expenses. Every adjustment we make counts toward improving productivity and profitability while maintaining high-quality service."

Was this helpful?