Restocking via Water Strider

Water Strider: A role in Lean manufacturing responsible for ensuring that workstations are fully stocked with materials, tools, and supplies, thereby minimizing the idle time workers spend fetching items.

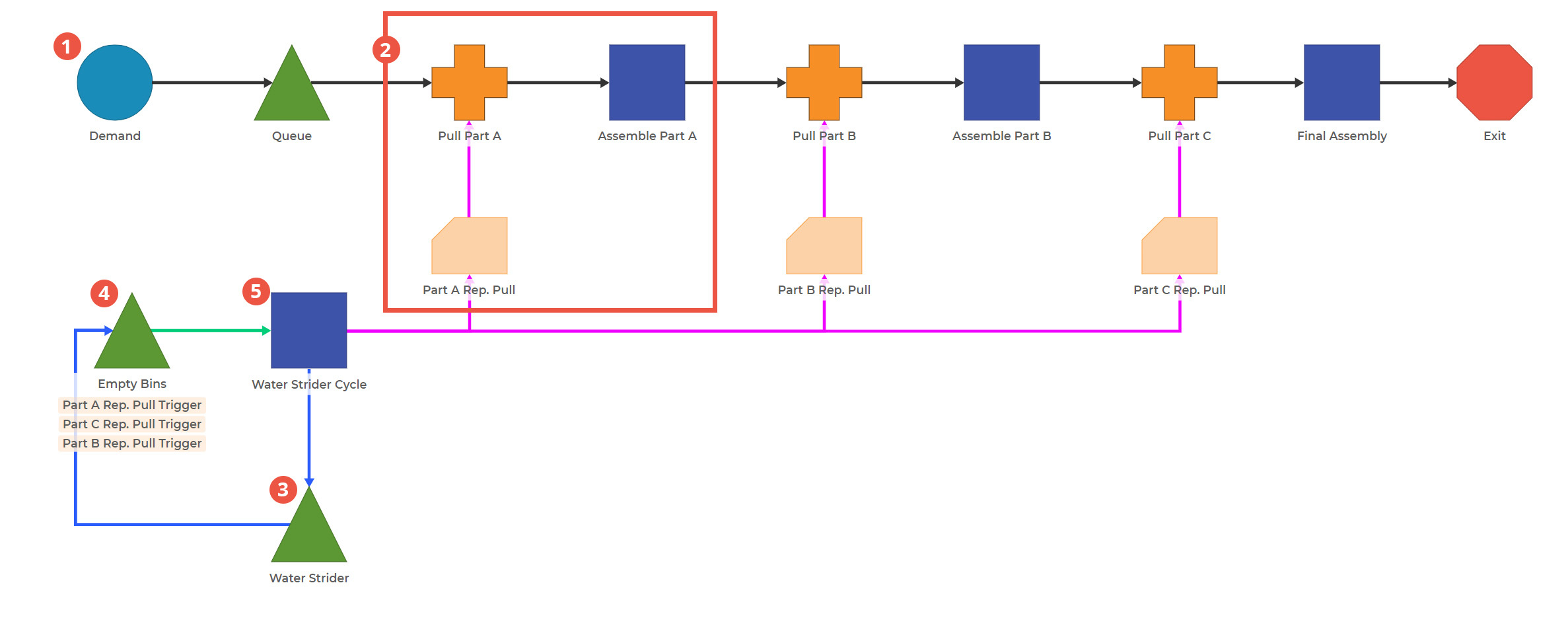

0. This model has eight items: Order, Part A, Part B, Part C, Order+A, Order+A+B, Order+A+B+C, and Water Strider Cycle.

1. Generate Orders. This block represents customer orders arriving to the process.

2. Model the Assembly Process. This block is repeated three times, adding a new part onto the assembly each time. The Replenishment Pull blocks are set up to resemble a two-bin system. When a bin is empty, it is "returned" to the "Empty Bins" queue (4) between each water strider cycle.

3. Initialize the Water Strider Cycle. The Water Strider Cycle item starts in this Queue Block and cycles around the loop, representing the delay between Water Strider cycles.

4. New items wait in the Empty Bins and get restocked at the end of each Water Strider Cycle. You can replace the green connector line with a full pick & pack process to represent the stockroom process, but this version simplifies that.

5. The Water Strider Cycle block serves two purposes. When a replenishment of Part A, B, or C is in the block, it represents the time to pull that replenishment and deliver it to the line. When the Water Strider Cycle item is in the block, it represents the downtime between replenishment cycles.

Another version of restocking, the Water Strider, in this case, makes rounds restocking parts after a fixed amount of time. This model can be used to determine the appropriate amount of time and sizing of bins necessary to minimize downtime.

Was this helpful?